The Oxygen Purity Analyzer is a key instrument designed for the precise measurement of oxygen (O₂) concentration and purity in various environments. It plays a critical role in ensuring quality, safety, and process efficiency. Its main applications span medical industries, diving operations, chemical processes, and heavy industries, where accurate oxygen level control according to international standards (such as ISO 8502 and NFPA 99) is essential.

Strategic Applications

Medical Industry

This device continuously monitors medical gases, such as therapeutic oxygen, ensuring that the oxygen delivered to patients matches prescribed concentrations. This not only enhances treatment effectiveness but also prevents complications caused by impure gases or abnormal oxygen levels.

Heavy Industry and Manufacturing Processes

In processes such as plasma welding, laser metal cutting, chemical synthesis, and controlled combustion systems, even minor deviations from optimal oxygen levels can reduce product quality, increase waste, or create hazardous conditions. The analyzer provides real-time data, enabling optimization of operational parameters and minimizing workplace risks.

Diving and Exploration

For diving and exploratory operations, the analyzer monitors respiratory gas mixtures, ensuring oxygen levels are safe according to depth and water pressure. It helps prevent oxygen toxicity or hypoxia, reducing operational costs, increasing efficiency, and maintaining advanced safety protocols.

Sensor Technologies

The thermo-paramagnetic sensor combines thermal conductivity and paramagnetic principles to measure oxygen concentration accurately in process gases. Oxygen, being paramagnetic, is attracted to magnetic fields, forming the basis for oxygen measurement in diverse gas environments.

How It Works:

The sensor consists of a temperature-controlled measurement chamber with a strong magnetic field. Oxygen gas flows between two thermistors (known as a “magnetic wind”), affecting heat transfer between them. This changes the thermistors’ electrical resistance, producing a signal proportional to oxygen concentration.

Key advantages of thermo-paramagnetic sensors:

– No moving parts or consumables: Reduced operating and maintenance costs.

– Dedicated calibration: High accuracy within the specified measurement range.

– Chemical resistance: Compatible with corrosive gases and difficult process conditions.

– Measurement stability: Provides stable and repeatable results over the long term.

– Favorable price-performance ratio: Economic efficiency combined with technical efficiency.

– Compact and safe design: Suitable for installation in hazardous or space-constrained environments.

– Long calibration period: Up to 6 months without the need for recalibration.

Combining thermodynamic and magnetic principles, this technology is recognized as an accurate, stable and cost-effective solution in the chemical, petrochemical and process control industries.

2. Zirconium oxide-based sensors

Zirconium oxide sensors operate on the principle of a solid-state electrochemical cell. In this technology, a layer of yttria-stabilized zirconium oxide is activated at a temperature of 600 to 700 degrees Celsius, allowing oxygen ions to migrate from a region of higher concentration to a region of lower concentration. This ionic movement results in the creation of an electromotive force (EMF) that is directly used to determine the oxygen concentration in the gas being analyzed.

Mechanism of operation of zirconium oxide-based sensors:

The difference in oxygen concentration on both sides of the zirconium layer, by generating a proportional voltage, allows for a wide range of measurements from 100% to less than 1 ppm (parts per million).

Four sensor models based on this technology:

– Metal Sealed Reference Sensor (MSRS)

– Zirconia Air Reference

– Mini Zirconium

– Micro Ion Pump Sensor (MIPS)

Advantages of the Metal Sealed Reference Sensor (MSRS):

– Ability to measure oxygen in a wide range of industrial applications

– Ability to measure in environments containing pure helium

– Fast response and stable recovery from ambient air level to 0ppm oxygen.

– Requires only one calibration gas for initial adjustment.

Advantages of Zirconia Air Reference

– Short response time to changes in oxygen concentration.

– High flexibility in multi-purpose applications

– Cost-effective with easy maintenance.

– Possibility of quick and uncomplicated calibration.

– Coverage of the measuring range of 1ppm to 25% or 0 to 96%.

Advantages of Mini Zirconium:

– Reduction of response time to less than 10 seconds (from ambient air level to ppm range).

– Long operating life of up to 3 to 5 years.

– Minimal interference with other gases in the environment.

– Low dependence of the sensor signal on temperature changes.

– High accuracy in the range of 0 to 50ppm.

Advantages of the Micro Ion Pump (MIPS) sensor:

– Easy installation and operation without the need for complex technical knowledge.

– Supports semi-automatic calibration using air or standard gases.

– Short warm-up time compared to other zirconium sensors.

– Measuring range coverage of 0.5 to 25% or 0.5 to 100%

Utilizing advanced electrochemical technology, these sensors are widely used as an accurate, fast and durable solution in industries such as petrochemicals, power generation, combustion control and environmental monitoring.

Key Advantages:

This technology provides a precise, stable, and cost-effective solution in chemical, petrochemical, and process control industries.

Zirconium oxide sensors operate on the principle of a solid-state electrochemical cell. A layer of yttria-stabilized zirconium oxide, heated to 600–700°C, allows oxygen ions to migrate from high to low concentration zones, generating an electromotive force (EMF) proportional to the oxygen content.

How It Works:

Oxygen concentration differences across the zirconium layer generate a voltage signal, enabling measurement ranges from 100% down to less than 1 ppm.

Main Sensor Models:

These sensors provide highly accurate, fast, and durable solutions for petrochemical, energy production, combustion control, and environmental monitoring.

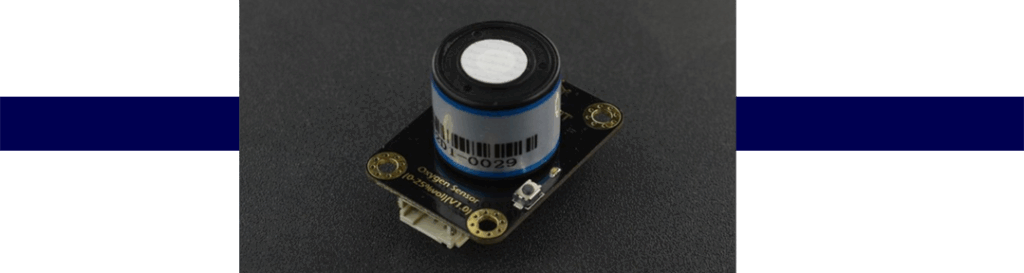

Galvanic oxygen sensors include a permeable membrane, electron-transferring electrolyte, lead anode, and cathode. Oxygen molecules diffuse through the membrane, react electrochemically at the cathode, and generate a current proportional to oxygen concentration.

Sensor Types:

Advantages:

Solid-State Ceramic Electrochemical Sensors:

Operate like galvanic sensors but use advanced ceramics for high chemical resistance and long lifespan, ideal for corrosive or harsh process conditions.

Safety Precautions and Guidelines

Warning Symbols

Follow Operational Instructions:

Ignoring safety instructions can result in personal injury or analyzer damage.

General Operating Instructions

Following these guidelines extends device life, ensures user safety, and maintains analytical accuracy. In abnormal conditions, turn off the device and contact technical support immediately.