A Dew Point Meter is an instrument designed to measure the dew point—the temperature at which air becomes saturated and water vapor begins to condense into liquid (dew). These devices are widely used across industries such as meteorology, HVAC (heating, ventilation, and air conditioning), food processing, pharmaceuticals, and industrial processes.

How It Works

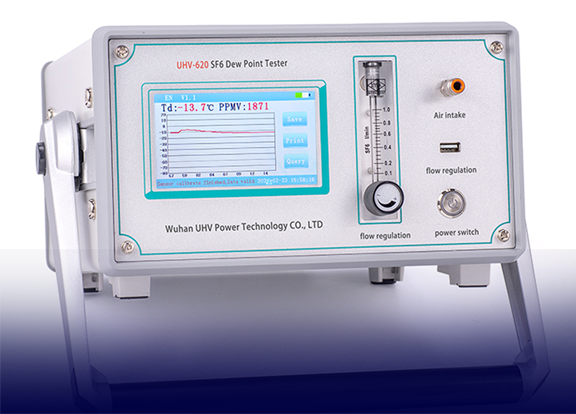

Dew point meters typically use a humidity sensor (capacitive or resistive) and a temperature sensor. By measuring relative humidity and ambient temperature, the dew point is calculated. Advanced models can measure the dew point directly.

Main Components

Applications of Dew Point Meters

Advantages

Working Principles of Dew Point Meters

One of the most accurate methods for measuring dew point:

Where:

Advanced meters can directly measure the dew point, typically used in industrial and high-precision applications.

Factors Affecting Accuracy

Types of Dew Point Meters

Key Features

Measurable Parameters

Important Considerations for Choosing a Dew Point Meter

Maintenance and Calibration

Regular Calibration

Ensures measurement accuracy, operational stability, compliance with standards, and extended device life.

Maintenance Methods

After-Sales Services

————————————————–

Sources: