O2 CAS Number 7782-44-7 UN1073 (refrigerated liquid)

Oxygen

O2|CAS Number 7782-44-7|UN1073(refrigerated liquid)

Calculating the volume or mass of a given amount of liquid

At the boiling point (1atm | 90.19k) Equal to: -182.96 C° || -297.33 F°

The phase diagram of a molecule shows the transition between solid, liquid, and gas phases as a function of temperature and pressure.

GHS03

Oxidising

GHS04

Gas under pressure

• Contact with Skin and Eyes: Liquid oxygen has an extremely low temperature of around -183°C (-297°F). Direct contact may cause severe frostbite and serious eye injuries. When handling LOX, appropriate personal protective equipment (PPE) must be used, including cryogenic gloves, face shields or safety goggles, and protective clothing.

• Fire and Explosion Hazard: LOX is a powerful oxidizer that dramatically increases the flammability of combustible materials. Contact with flammable substances such as oils, greases, organic matter, and fuels must be strictly avoided. Even dust or fabric fibers can ignite in the presence of LOX. Never use containers or tools contaminated with grease or oil near LOX.

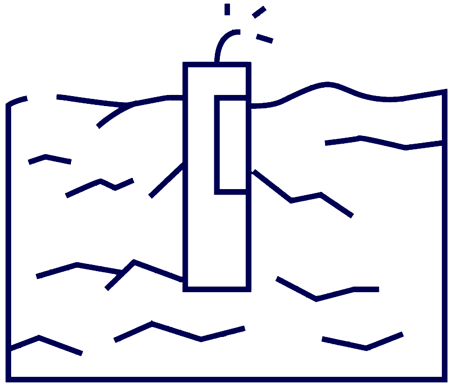

• Pressure and Vaporization: As LOX rapidly vaporizes, its volume expands approximately 860 times. Storage vessels must be pressure-rated and equipped with proper pressure relief systems to handle this expansion. Sealed containers of LOX must never be left unattended, as excessive pressure buildup may lead to explosive rupture.

• Compatible and Incompatible Materials: Only compatible materials should be used in equipment and containers. Metals such as stainless steel, aluminum, and copper are generally safe for use with LOX. In contrast, some plastics, rubbers, and other materials can become brittle or chemically reactive at cryogenic temperatures and must be avoided.

• Proper Ventilation: LOX should always be handled in well-ventilated areas to prevent the accumulation of oxygen vapor, which could increase the risk of fire and combustion in confined spaces.

• Personnel Training: All personnel involved in the handling of LOX must receive comprehensive training on its hazards and safety protocols.

• Proper Equipment Use: Containers and equipment should be specifically designed for LOX, including necessary safety mechanisms such as relief valves and insulation systems.

• Transport and Transfer: Only approved hoses and fittings rated for LOX service should be used. Avoid shocks, impacts, or vibrations during transfer operations.

• Storage Conditions: Store LOX in cryogenic vacuum-insulated containers placed in cool, dry, and well-ventilated areas, far from flammable materials and heat sources.

• Leak Management: In case of a leak, evacuate the area immediately, identify the source, and eliminate it if safely possible. Prevent any ignition sources from entering the vicinity.

• First Aid Response: In the event of skin or eye exposure to LOX, rinse the affected area thoroughly with large amounts of water and seek immediate medical attention.