This post is also available in: Persian Armenian

Over the past few decades, compressed gases have played a key role in the development of industrial, sporting, and even research equipment. One important—but often less publicized—application is the use of carbon dioxide (CO₂) as an energy source and propellant in airguns, shooting simulators, paintball markers, and industrial gas-pressure systems.

At first glance, one might assume that weapons operate solely via mechanical or combustion-based mechanisms. In reality, a wide range of modern projectile devices rely on a controlled pressure source that must be precise, stable, cost-effective, and safe. Thanks to its specific thermodynamic properties, CO₂ has secured a very important place in this field.

Why Is CO₂ Chosen for Gas-Pressure Weapons?

1. Thermodynamic Properties That Fit the Application

1. Thermodynamic Properties That Fit the Application

Carbon dioxide is one of the few gases that can be liquefied easily at near-ambient temperatures and moderate pressures. This has several important consequences:

- High energy density

A relatively small volume of liquid CO₂ can store a significant amount of compressed energy. This is why a compact 12 g CO₂ cartridge can power dozens of shots. - Relatively stable pressure during use

As long as a meaningful amount of CO₂ remains in the liquid phase, the outlet pressure remains relatively stable. This leads to consistent performance from shot to shot. - Safe storage characteristics

Unlike gases such as hydrogen or acetylene, CO₂ is non-flammable and does not pose an ignition risk if a leak occurs. This makes it particularly suitable for sporting and training applications.

2. Availability and Cost

CO₂ is inexpensive and readily produced on an industrial scale. It is generated as a byproduct in:

- petrochemical complexes,

- refineries,

- gas sweetening units,

- and even in beverage production plants.

As a result, the supply of CO₂ for airgun manufacturers, paintball facilities, and training centers is both reliable and economical.

3. Stable Behavior in Small Containers

Gases such as compressed air (HPA) require reinforced cylinders and high-pressure compressors. In contrast, liquid CO₂ is stable at around 800 psi (≈ 55 bar) at room temperature and can be stored in small containers such as 12 g, 16 g, and 88 g cartridges.

4. Expansion Rate Suitable for Launch Applications

When liquid CO₂ exits the reservoir and flashes into gas, the expansion is rapid and intense. This expansion provides the kinetic energy needed to launch:

- pellets or BBs,

- paintballs,

- and other non-lethal projectiles.

Operating Principle of CO₂ in Weapon Systems

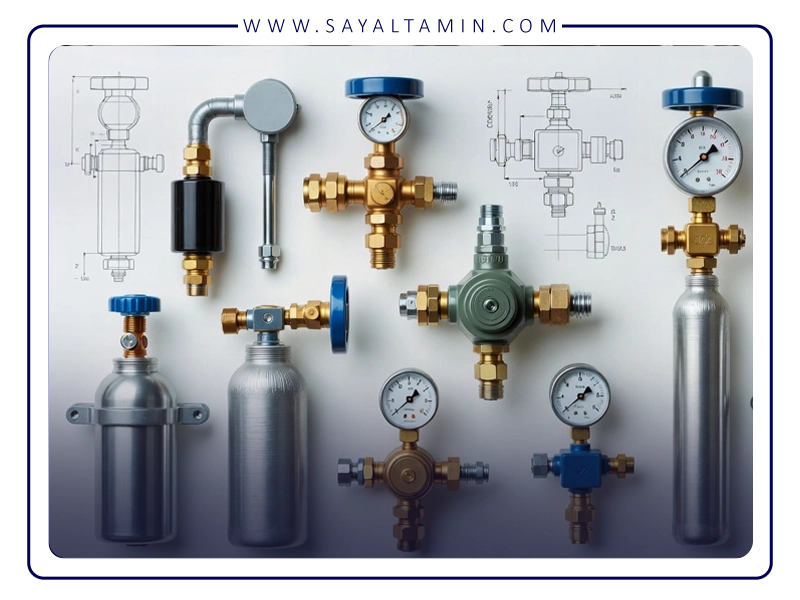

1. Basic Architecture of a CO₂ System

A typical CO₂-powered gun consists of the following components:

- CO₂ cartridge or reservoir (12 g or larger),

- piercing pin or puncture needle,

- pressure control valve or regulator,

- firing chamber,

- barrel,

- trigger mechanism.

Key point:

Inside the cartridge, CO₂ exists primarily as a liquid, with a small headspace of gas in equilibrium with it. The gas phase determines the internal pressure.

2. Firing Cycle with CO₂

In simplified form, the firing sequence is as follows:

- Pulling the trigger actuates the valve.

- A metered quantity of CO₂ gas flows from the reservoir into the firing chamber.

- The gas rapidly expands and accelerates the projectile down the barrel.

- The valve closes and pressure in the reservoir returns to equilibrium as more liquid CO₂ evaporates.

This entire cycle happens in just a few milliseconds.

3. The Role of Temperature

One of CO₂’s most important characteristics in this context is its strong temperature dependence.

- At higher temperatures, CO₂ generates higher pressures.

- At lower temperatures, the pressure drops significantly.

Practical effects:

- In cold weather:

- Internal pressure decreases → muzzle energy drops.

- In hot weather:

- Internal pressure rises → gas consumption and projectile velocity may change.

This temperature sensitivity is a built-in challenge of CO₂ systems and must be accounted for in weapon and system design.

Historical Use of CO₂ in Weapons

The use of CO₂ in projectile systems dates back several decades:

- 1950s: the first commercial CO₂ airguns were introduced.

- 1970s: use of CO₂ expanded into military and law-enforcement training simulators.

- 1990s: CO₂ reached its peak popularity in paintball, becoming the de facto standard.

Today, despite the spread of High-Pressure Air (HPA) systems, CO₂ remains widely used in:

- recreational airguns,

- training devices,

- recreational paintball,

- low-intensity military and security simulators,

- certain industrial safety tools,

- laboratory impact testers and non-lethal projectile devices.

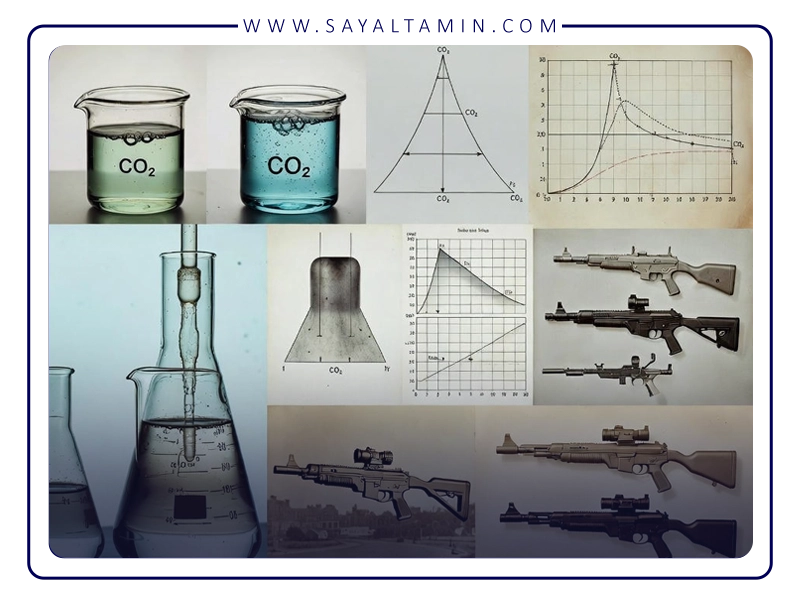

Types of CO₂-Based Weapons and Devices

1. CO₂ Airguns (Rifles and Pistols)

CO₂-powered rifles and pistols are among the most common gas-pressure devices. They use the rapid expansion of CO₂ to launch:

- BBs,

- pellets,

- or other lightweight projectiles at controlled energy levels.

Their key characteristic is a balanced combination of power, safety, and low operating cost.

Typical applications:

- Recreational shooting

For backyard plinking, informal target shooting, or shooting ranges, CO₂ systems offer smooth, predictable performance with low recoil. - Marksmanship training

CO₂ airguns are widely used to train aiming skills and trigger control. Unlike HPA guns, they do not require heavy compressor infrastructure, making them attractive for clubs and entry-level facilities. - Small pest deterrence

In some agricultural settings, CO₂ airguns with limited power are used as deterrents to keep birds or small animals away, typically with the aim of minimal harm. - Low-power sport shooting disciplines

Competitions using light pellets or BBs rely on stable pressure and consistent velocity. CO₂’s relatively constant pressure (while liquid remains) makes it a dependable option.

Key features:

- Very low felt recoil, since energy does not come from combustion.

- Lower and more consistent noise levels, valuable in training environments.

- Simpler internal mechanisms with fewer moving parts, leading to reduced wear and easier maintenance.

2. Paintball Markers

Paintball markers are one of the best-known examples of CO₂ usage. Paintballs are gelatin capsules filled with dye that require moderate, consistent, and safe launch energies—and CO₂ delivers exactly that.

Why CO₂ is suitable for paintball:

- Moderate but stable propulsive power

Paintballs are fragile. Excessive pressure can cause them to rupture in the barrel. CO₂’s self-regulated pressure (within a given temperature range) supports stable shot-to-shot performance. - Low operating cost

Paintball fields often manage tens or hundreds of markers simultaneously. CO₂ is inexpensive and refilling infrastructure is relatively simple, making it ideal for this business model. - Support for semi-automatic firing

CO₂ expansion can supply sufficient energy for repeated shots, especially in semi-automatic configurations.

Practical observations:

- Field performance is strongly influenced by ambient temperature. In cold weather, muzzle velocity can drop noticeably.

- Many professional players have moved to HPA, but CO₂ remains a popular and cost-effective choice for recreational play.

- Facilities frequently maintain bulk CO₂ tanks on-site to refill player cylinders.

3. Training Simulators

Training simulators are used in security, law enforcement, and protective services training centers. These devices are designed to mimic real firearms in:

- handling,

- trigger behavior,

- and sometimes recoil characteristics—

but without the hazard associated with live ammunition.

The role of CO₂ in simulators:

- Simulated recoil or blowback

Some training pistols and rifles use CO₂ to generate mechanical blowback, providing a more realistic shooting sensation. - Controlled performance in training environments

Because CO₂ operates within a well-defined pressure range, the risk of serious injury is significantly reduced compared to live ammunition. - Lower cost compared to fully electronic or complex pneumatic systems

CO₂ can supply the required mechanical energy using a simple cartridge, avoiding bulky cables, batteries, or heavy compressors.

These simulators enable:

- scenario-based training without live rounds,

- familiarization with weapon ergonomics and trigger behavior,

- realistic drills in controlled, low-risk environments.

4. Industrial and Research Gas-Pressure Systems

Beyond sports and training, CO₂ plays an important role in various industrial and laboratory systems as a controllable pressure source or launch medium.

Examples include:

- Laboratory launch and impact devices

CO₂ systems are used to launch test specimens or perform impact tests for materials research. - Engineering education systems

Universities and technical institutes employ CO₂-based setups to demonstrate fluid dynamics, gas expansion, and pressure behavior. - Material and structural testing

CO₂ can be used as a controllable force source for launching small projectiles in strength and penetration tests. - Impact measurement rigs

Where a controlled, repeatable impact is required without additional heat or chemical byproducts, CO₂ offers a clean and predictable solution.

Key features:

- Non-flammability makes CO₂ safer than reactive gases in sensitive lab environments.

- The energy release is highly predictable, making it suitable for controlled experimental setups.

- Low cost supports frequent, repeatable testing in research and industrial contexts.

Technical Characteristics of CO₂ in Weapon Systems

1. Operating Pressure

At approximately 21 °C (room temperature), liquid CO₂ in a closed cylinder generates a pressure of about 800 psi (≈ 55 bar).

This pressure arises naturally from the liquid–gas equilibrium and does not require compressors or external pressurization equipment.

Why this matters:

- Sufficient for safe launch energies

The pressure is adequate for launching lightweight projectiles, paintballs, or for driving mechanical training mechanisms, without approaching the extremely high and hazardous pressures used in some other systems. - Compatible with compact, lightweight cylinders

CO₂ containers are typically simpler and lighter than HPA tanks. - Nearly constant pressure while liquid remains

As long as some liquid CO₂ is present, any pressure drop is compensated by further evaporation, which restores the equilibrium pressure—assuming temperature remains constant.

This self-regulating behavior is one of the main reasons CO₂ is attractive for simple systems.

2. Temperature–Pressure Relationship

CO₂ behavior is strongly tied to temperature, more so than compressed air.

Unlike HPA, where pressure mainly depends on the amount of gas and tank volume, CO₂ pressure is governed primarily by temperature (as long as liquid is present).

Examples:

- At higher temperatures (≈ 30–35 °C):

- Cartridge pressure increases.

- Muzzle energy can rise.

- Gas consumption per shot may change.

- At lower temperatures (≈ 5–10 °C):

- Pressure drops significantly.

- Projectile velocity decreases.

- Some guns may exhibit unstable performance.

Scientific explanation:

When liquid CO₂ evaporates, it absorbs heat (latent heat of vaporization). In cold conditions, the environment cannot supply this heat quickly enough, so the evaporation rate and thus the internal pressure decrease.

3. Expansion Behavior and the Joule–Thomson Effect

When CO₂ expands from high pressure to low pressure—especially when it transitions from liquid to gas—it undergoes pronounced cooling due to the Joule–Thomson effect. This is very noticeable in CO₂ guns.

Consequences:

- Pressure drop during rapid fire

Cooling reduces evaporation rates, leading to a temporary decrease in reservoir pressure during strings of rapid shots. - Cooling of the barrel and components

After 10–15 rapid shots, the barrel or valve area may become significantly cold. - Frost accumulation on the cartridge

Moisture from the surrounding air can freeze on the cartridge body, forming a visible white frost layer.

Why this matters:

- Users must understand that rapid-fire sequences can affect performance through cooling.

- Designers take this into account by using appropriate alloys and geometries to minimize icing and maintain functionality.

Advantages and Limitations of CO₂

Benefits

1. Low price

|

2. Easy storage and handling

|

3. Higher safety compared to reactive gases

|

4. Stable performance under normal use

|

5. Suitable for repeated firing

|

| 6. Compatibility with compact and lightweight designs |

- CO₂ guns often have lower weight and smaller form factor, improving ergonomics and portability.

Limitations

| 1. Pressure drop at low temperatures |

- Because CO₂ needs heat to evaporate, performance in cold weather is significantly reduced.

2. Strong sensitivity to ambient temperature

- Even relatively small temperature changes can noticeably affect internal pressure and muzzle velocity.

3. Limits on maximum output power

- CO₂ cannot easily reach the very high velocities achievable with HPA.

- For high-performance competition use, HPA is often preferred.

4. Dependence on cartridge quality

- Performance is directly tied to cartridge manufacturing quality.

- Low-grade cartridges may contain less CO₂ or exhibit poor sealing.

Design of CO₂ Cylinders and Cartridges

CO₂ cartridges are usually made from single-piece steel bodies designed to withstand high internal pressures.

Technical characteristics:

- Seamless steel construction

Minimizes the risk of rupture or leakage. - Filled with liquid CO₂

Approximately 80–90% of the internal volume is filled with liquid, with the remainder forming the gas headspace that establishes pressure. - No built-in valve

Cartridges are activated only when pierced by the gun’s puncture pin. - Long shelf life

In the absence of leakage or corrosion, CO₂ remains contained and stable for years.

Common sizes:

- 12 g – typical for pistols and compact rifles.

- 16 g – used in some semi-professional or specific paintball setups.

- 88 g – for more powerful rifles requiring larger shot counts.

- Refillable bulk cylinders – used by clubs and industrial users.

Comparison: CO₂ vs High-Pressure Air (HPA)

| Feature | CO₂ | HPA |

| Cost | Very low | Higher |

| Pressure | Stable but temperature-dependent | Very stable, largely temperature-independent |

| Tanks | Small, light, simple | Larger, heavier, reinforced |

| Typical use | Recreational, training, paintball | Professional, competition, high-performance |

| Maintenance | Simple | Requires compressor / fill station |

Conclusion of comparison:

CO₂ is excellent for general-purpose, recreational, and training applications, whereas HPA is better suited to high-precision, competition, and professional scenarios.

Safety and Industrial Considerations

Chemically, CO₂ is relatively benign, but from a pressure and physical standpoint it must be handled with care:

- Never expose cartridges or cylinders to excessive heat or direct flames.

- Device components in contact with CO₂ should be made from appropriate steel or high-strength alloys.

- Avoid extremely rapid sustained firing, as excessive cooling can affect performance and mechanical integrity.

- Use standard-compliant cartridges bearing CE, ISO, or equivalent certification marks.

Industrial Opportunities Linked to CO₂ Supply

Companies active in industrial gases, energy, and condensates can play a key role in supplying CO₂ to this market segment. Potential business areas include:

- Supplying CO₂ to airgun and training-weapon manufacturers,

- Providing CO₂ to paintball fields and recreational centers,

- Supplying gas to training simulator manufacturers and operators,

- Serving research and testing laboratories using CO₂-based launch or impact systems,

- Packaging and distributing CO₂ in small cartridges for sporting and industrial end users.

This market is typically stable, demand-driven, and relatively low-risk, with recurring consumption.

Carbon dioxide is one of the world’s most important industrial gases. Beyond its well-known roles in the petrochemical, food, and medical sectors, it has a significant and versatile role in gas-powered weapon systems.

Key attributes—such as:

- high energy storage density,

- ease of liquefaction,

- self-regulating pressure behavior,

- and low cost—

have made CO₂ the dominant gas for light projectile devices, paintball markers, training airguns, and many laboratory and industrial impact systems.

This article has explored CO₂’s role from thermodynamic, engineering, industrial, and practical perspectives, showing why it remains a preferred choice in many gas-pressure applications.

For companies operating in the gas and energy sectors, high-quality CO₂ is not just a commodity—it is a value-added product that supports a broad, steady, and evolving market ranging from sports and training to research and specialized industrial equipment.

————————————————–

References

1. Beckstrom, P., & Tepper, J. (2019). Principles of Gas-Powered Airguns. Airgun Technology Press.

2. Crossman, E. C. (2020). CO₂ Power Systems in Small Arms: Engineering and Performance. Ballistic Research Journal.

3. Smith, R. (2018). Gas Dynamics in CO₂ and HPA Airguns. Journal of Applied Ballistics, 14(3), 122–138.

4. Brown, M., & Keller, S. (2021). Thermodynamics of Compressed Gases in Sporting Arms. International Journal of Pressure Vessel Engineering.

5. Paintball Manufacturers Association (PMA). (2020). CO₂ vs. HPA Systems: Operational Guidelines & Safety Considerations.