This post is also available in: Persian Armenian

Introduction

The fisheries industry is one of the most important and dynamic sectors of agriculture and food production worldwide. In recent decades, with the growing global population and the increasing demand for high-quality protein sources, fish and shrimp farming have become strategic industries. One of the key factors for the success and sustainability of this sector is the proper management of dissolved oxygen levels in water.

Oxygen is the most vital element for the survival of aquatic organisms. A lack of oxygen in fish ponds can quickly lead to reduced growth, higher mortality rates, and increased stress among fish. On the other hand, the optimal injection and control of oxygen gas can significantly enhance growth and production efficiency.

The Importance of Oxygen in Aquatic Life

Just as humans need oxygen to breathe, fish and other aquatic organisms obtain it from the water. Dissolved Oxygen (DO) enters the water through various processes such as gas exchange at the water’s surface, photosynthesis by aquatic plants, and the injection of compressed air.

However, unlike air, water has a very limited capacity to hold oxygen. High temperatures, organic pollution, and high fish density can all lead to reduced dissolved oxygen levels. As a result, even minor fluctuations in oxygen concentration can have serious consequences for the entire pond ecosystem.

Typically, the optimal dissolved oxygen level for most fish species ranges between 5 to 8 mg/L. When the level drops below 3 mg/L, stress, loss of appetite, and increased mortality are likely to occur. Therefore, continuous monitoring and the controlled injection of pure oxygen are of critical importance.

The Role of Oxygen in Fish Growth and Health

Oxygen is involved in several metabolic processes in aquatic organisms. In the absence of sufficient oxygen, fish metabolism slows down and growth slows down. Oxygen deficiency also leads to the accumulation of carbon dioxide and ammonia in the water, both of which are toxic to fish.

Growing fish, especially species such as trout, carp, and farmed shrimp, require large amounts of oxygen. The use of industrial oxygen gas in such systems results in:

• Increased growth rate and final weight of fish;

• Reduced mortality due to suffocation or stress;

• Increased feed conversion ratio;

• Reduced diseases and infections caused by poor environmental conditions.

For this reason, many modern fish farming units in the world use direct injection systems of liquid oxygen (LOX) or compressed gas.

Methods of supplying oxygen in the fisheries industry

Dissolved oxygen can be supplied to the water in several ways. Below, we review the most common methods:

a) Mechanical aeration

In this method, devices such as paddlewheels, airlifts, or air compressors circulate the water and bring more air into contact with the water surface. The advantage of this method is its simplicity and low initial cost, but in pools with high density, mechanical aeration cannot fully meet the oxygen requirement.

b) Air injection with a compressor

In this method, air is introduced into the pool through pipes and diffusers. Although this method is more efficient than mechanical aeration, its efficiency is limited because only 21% of compressed air is oxygen.

c) Pure oxygen gas injection

The use of industrially pure or liquid oxygen is one of the most advanced and effective methods of supplying oxygen. In these systems, high-purity oxygen (more than 99.5%) is injected into the pool from storage tanks or capsules. This method is widely used in high-density breeding farms and closed-loop systems (RAS).

Sial Tamin Company meets the needs of small and large fishing farms across the country by supplying high-purity compressed and liquid oxygen gas.

Benefits of using pure oxygen in fisheries

Pure oxygen gas injection has several advantages over traditional methods, including:

1. Significantly increased production efficiency:

Fish grow faster and consume more efficiently in an environment with sufficient oxygen.

2. Reduce stress and losses: Reducing oxygen fluctuations at night or in hot weather helps maintain herd health.

3. Better control of water quality: Oxygen oxidizes organic matter and reduces unpleasant odors in the water.

4. Improving the performance of the biological filter system in RAS:

In closed-loop systems, the activity of nitrifying bacteria is dependent on oxygen.

5. Reduced energy consumption: Compared to mechanical aeration, direct injection of pure oxygen is more efficient and consumes less electricity.

6. Can be used in critical situations: During transportation or in hot summer weather, pure oxygen injection can prevent casualties.

Applications of oxygen gas in various sectors of the fisheries industry

Oxygen gas plays a fundamental and multifaceted role in the entire fisheries industry chain — from the stage of reproduction and rearing of juvenile fish to the final processing and transportation of products. The importance of this gas is not limited to meeting the respiratory needs of fish; it also has a direct impact on water quality, biological health, the performance of filtration systems, and even increasing the shelf life of fishery products.

The most important areas of oxygen use in the fisheries industry

1. During the reproduction and rearing stage of fry

In hatcheries, fish eggs are kept in very sensitive and controlled conditions. Any reduction in dissolved oxygen can cause reduced hatching rates, embryonic losses, and developmental abnormalities.

At this stage:

• Oxygen is essential to meet the needs of the eggs and larvae, as they are not yet able to swim and seek out oxygen-rich areas.

• In spawning tanks, injecting pure oxygen gas increases the survival rate and promotes more uniform growth of larvae.

• Using high-purity industrial oxygen (over 99%) in stagnant water prevents the growth of anaerobic bacteria and fungi.

In large trout, whitefish, and shrimp farms, oxygen generators are used to continuously supply oxygen to maintain high fish densities without stress or loss.

2. During the growth and breeding stage in pools and open systems

In this section, the goal is to maintain the dissolved oxygen level within the ideal range (5 to 8 mg/L). In ponds with high density or high temperatures, oxygen is consumed rapidly and even a few hours of oxygen depletion can lead to heavy losses.

The injection of pure oxygen gas has the following advantages:

• Increased growth and final weight of fish: Because more oxygen allows for better metabolism and more efficient feed consumption.

• Reduction of ammonia and nitrite accumulation: In the presence of oxygen, the nitrification process is carried out well and dissolved toxins are reduced.

• Reduce mechanical aeration costs: On many farms, the use of oxygen replaces part of the electricity consumption of paddlewheels and compressors.

• Increased uniformity of stock growth: In ponds where oxygen is injected uniformly, the size difference between fish is reduced and feeding management becomes easier.

Sial Tamin Company allows industrial aquaculture farms to use cylinder oxygen injection systems or central lines to precisely control DO levels.

3. In closed circuit systems (RAS)

RAS systems, or Recirculating Aquaculture Systems, are one of the most modern fish farming methods in which more than 90% of the water is recycled. In such systems, every part — from the biological filter to the growth tanks — requires sufficient oxygen.

In these systems:

• Pure oxygen is essential to maintain the activity of nitrifying bacteria in the biological filters;

• Injecting oxygen into the water at key points in the system (such as the filter outlet and tank inlet) stabilizes chemical parameters;

• Using pure oxygen reduces the need for water changes, saves energy, and increases the acceptable density of fish.

In fact, without a continuous supply of oxygen, a RAS system will quickly experience fluctuations in water quality and filter performance. Sial Tamin Company is one of the main suppliers of high-purity liquid and gaseous oxygen required for these systems.

4. In the transportation of live aquatic animals

Transporting fish or shrimp, especially over long distances, is one of the most sensitive stages in the fisheries chain. In transport tanks, the limited space and high density cause the available oxygen to be consumed quickly.

In such situations:

• Using oxygen gas cylinders for direct injection into tanks keeps the dissolved oxygen level constant.

• This reduces stress, prevents suffocation, and increases the lifespan of live fish in the tank.

• In air or ground transportation of fry, a combination of plastic bag + water + oxygen gas is usually used, which can create stable conditions for several hours.

In addition, the use of high-purity oxygen in transportation helps maintain the physiological quality of the fish after it reaches its destination and reduces the likelihood of disease.

5. In processing, packaging and storing fishery products

After harvest, oxygen still plays a role in maintaining quality, but its application here is different and is more prevalent in the processing and refrigeration sectors.

In fish and shrimp processing plants:

• Liquid oxygen (LOX) is used for flash cooling and instant freezing of products;

• In some packaging lines, a combination of oxygen with protective gases such as carbon dioxide and nitrogen is used in the modified atmosphere packaging (MAP) process to preserve the freshness of fish meat and inhibit the growth of microorganisms;

• In washing and cleaning lines, oxygen oxidizes unpleasant odors and reduces organic pollutants;

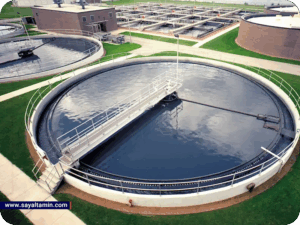

• In wastewater treatment systems of fishery factories, oxygen injection increases the rate of decomposition of organic materials and reduces the environmental pollution load.

6. In restoring habitats and improving natural water quality

Oxygen is not only used in artificial cultivation; it also plays a vital role in the protection of natural ecosystems. In wetlands, lakes and rivers that have suffered from oxygen deficiency (hypoxia) due to organic pollution, industrial effluent or excessive algae growth, oxygen injection is one of the most effective restoration methods.

Natural water regeneration processes are usually slow, but injecting pure oxygen can:

• Rapidly increase dissolved oxygen in deep water layers;

• Accelerate the decomposition of organic matter and bottom sludge;

• Reduce unpleasant odors and toxic gases such as hydrogen sulfide (H₂S);

• Make the habitat more suitable for the return of fish and aquatic plants.

In European and East Asian countries, mobile oxygen injection units are used to revitalize rivers. Sial Tamin Company, with its ability to supply oxygen gas in large volumes and deliver it to the project site, can play an industrial support role in such programs.

Control and measurement of dissolved oxygen levels

Oxygen management in fish farms is not possible without accurate instrumentation. DO (Dissolved Oxygen) sensors are usually used to measure the oxygen level in real time.

It is recommended to:

• Monitor dissolved oxygen regularly during the night;

• Increase oxygen injection in hot weather or during heavy feeding;

• Use automatic alarm systems in case of oxygen depletion.

Tips for buying and pricing oxygen gas for fisheries

The price of industrial oxygen gas is determined by several factors:

1. Gas purity: For fisheries applications, purity above 99% is recommended.

2. Packaging Type: Oxygen is supplied in compressed capsules, liquid tanks (LOX), or distribution lines.

3. Quantity and transportation distance: Purchase volume and distance from the factory have a direct impact on the final cost.

4. Energy and Condensate Market Fluctuations:

Since oxygen production is dependent on air separation processes, changes in energy and fuel prices also affect prices.

By utilizing modern air separation equipment (ASU) and an extensive distribution network, Sial Tamin Company is able to provide industrial and liquid oxygen to its fishing industry customers at competitive prices and fast delivery.

Oxygen is a critical component of successful fish and shrimp farming. Without proper control of dissolved oxygen levels, even the best farming systems cannot achieve optimal performance. Using pure oxygen gas not only increases the growth and health of aquatic animals, but also reduces losses, improves water quality, and saves energy.

As one of the most reputable suppliers of industrial gases in the country, Sial Tamin Company is ready to cooperate with all aquaculture units, research centers, and fishery processing companies. The company’s products include industrial oxygen gas, liquid oxygen, injection equipment, and technical consulting in the field of installation and operation.

By using fluid supply services, fisheries units can reduce their operating costs and raise production efficiency to world standards while ensuring the quality of the oxygen consumed.

————————————————–

References

1. FAO Fisheries Technical Paper on Oxygen Management in Aquaculture.

2. Aquaculture Engineering Journal, Elsevier.

3. American Fisheries Society, “Guidelines for Oxygenation in Fish Cul