This post is also available in: Persian Armenian

Water desalination refers to the removal or reduction of dissolved salts and minerals from saline or brackish water to produce freshwater suitable for drinking, industrial, or agricultural use. Over recent decades, population growth, climate change, and the depletion of freshwater resources have significantly increased the strategic importance of desalination technologies.

Despite their effectiveness, desalination systems face persistent challenges, including scaling, corrosion, membrane fouling, and efficiency losses, all of which increase operational costs and reduce equipment lifetime. Consequently, engineers and researchers are continuously exploring methods to optimize desalination processes and improve system reliability.

One of the most effective yet often underutilized approaches is the controlled application of oxygen as a chemical and process agent within desalination systems. Oxygen plays a critical role not only in water quality management but also in mitigating scaling, controlling corrosion, and enhancing the long-term performance of desalination equipment.

When properly controlled, oxygen injection can significantly reduce common operational issues and increase overall system efficiency, making it a valuable tool in modern desalination engineering.

Importance of Oxygen in Desalination Processes

Oxygen is widely used in water and wastewater treatment industries, and its impact on desalination processes is both broad and multifaceted. The role of oxygen in desalination can be summarized in two primary functions:

1. Oxidation and Removal of Contaminants

Saline and brackish waters often contain dissolved metal ions such as iron and manganese. These ions can cause discoloration, membrane fouling, and severe scaling issues. Oxygen oxidizes these dissolved metals into insoluble hydroxides or oxides, which can then be removed through filtration or sedimentation.

Additionally, oxygen can oxidize resistant organic compounds and sulfur-based species, converting them into less problematic forms and improving overall water quality.

2. Corrosion and Scaling Management

Desalination systems consist of pumps, membranes, boilers, and metallic pipelines. Without proper control, corrosion and scaling can significantly reduce equipment lifespan and increase maintenance costs. Controlled oxygen application enables the formation of protective oxide layers on metal surfaces, reducing uncontrolled corrosion and inhibiting mineral scale deposition.

Understanding the chemical mechanisms of oxygen interaction with water constituents and construction materials is essential for its effective and safe implementation.

Mechanisms of Oxygen Action in Desalination

Oxidation of Dissolved Metals

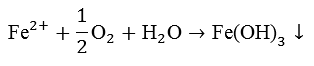

Dissolved iron and manganese present in saline water can create operational problems. When exposed to oxygen, these ions undergo oxidation reactions such as:

The resulting insoluble hydroxides can be efficiently removed by filtration, leading to improved water clarity, reduced membrane fouling, and enhanced taste and odor quality.

Removal of Refractory Organic Compounds and Odors

Oxygen is also used in combination with Advanced Oxidation Processes (AOPs) to degrade refractory organic compounds such as phenols, aromatic hydrocarbons, and sulfur-containing substances. These reactions convert complex pollutants into simpler, less harmful molecules, significantly reducing unpleasant odors and improving water palatability.

Scaling Control

Scaling caused by calcium carbonate, sulfates, and metal compounds can severely impair desalination systems. Proper oxygen dosing promotes the formation of stable oxide layers on metallic surfaces, acting as a protective barrier and reducing uncontrolled mineral deposition on membranes and pipelines.

Oxygen Injection Methods in Desalination

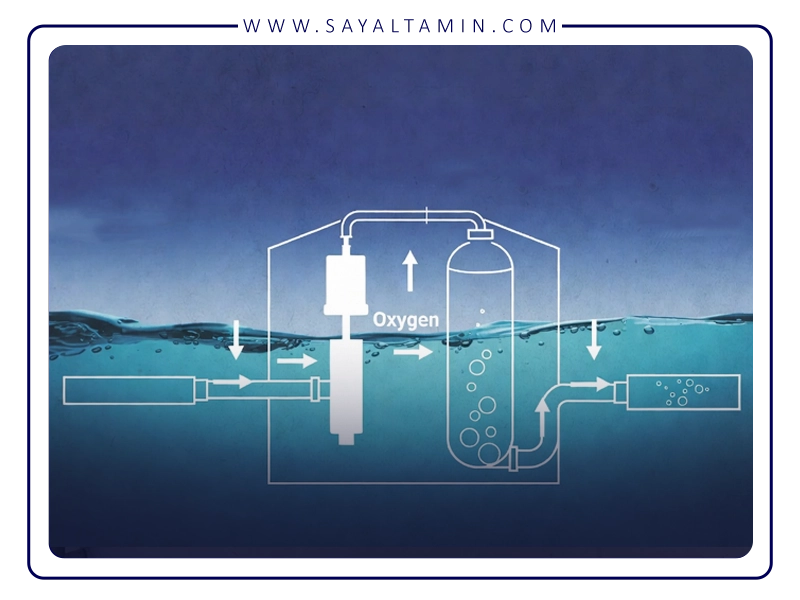

Direct Oxygen Gas Injection

In this method, pure or oxygen-enriched gas is injected directly into the water stream. It is commonly applied for:

- Oxidation of dissolved metals

- Removal of sulfur compounds and organics

- Scaling mitigation

This method offers precise control of dissolved oxygen levels but requires oxygen-compatible equipment and strict safety measures.

Aeration and Oxygen-Releasing Chemicals

Aeration systems or oxygen-releasing chemicals (such as peroxides) can be used to increase dissolved oxygen levels. These approaches are often preferred in smaller systems or where safety concerns limit the use of pure oxygen.

Oxygen in Advanced Oxidation Processes (AOPs)

In AOPs, oxygen is combined with UV radiation or chemical oxidants to generate highly reactive hydroxyl radicals. These radicals effectively destroy persistent organic contaminants and microorganisms, greatly enhancing treated water quality.

Benefits of Oxygen Application in Desalination

Improved Water Quality

Increased dissolved oxygen levels enable efficient removal of metals, sulfur compounds, and organic contaminants. The resulting water is clearer, odor-free, and suitable for potable and industrial applications.

Reduced Scaling and Corrosion

Controlled oxygen exposure facilitates the formation of protective oxide layers, reducing corrosion and preventing severe scale formation. This is particularly beneficial in reverse osmosis (RO) systems, where membrane fouling is a critical issue.

Enhanced Process Efficiency

Oxygen-assisted systems typically exhibit higher contaminant removal efficiency and reduced chemical consumption, leading to lower operational costs and improved energy efficiency.

Limitations and Safety Considerations

- Fire and Explosion Risk: Oxygen-enriched environments increase flammability risks and require strict safety controls.

- Oxidative Corrosion: Excessive oxygen concentrations can accelerate material degradation.

- Process Control Requirements: Precise dosing and continuous monitoring are essential to maintain benefits while avoiding adverse effects.

Comparison of Oxygen Use in Different Desalination Technologies

| Desalination Method | Role of Oxygen | Key Benefits | Limitations |

| Reverse Osmosis (RO) | Metal oxidation, contaminant removal | Extended membrane life, reduced fouling | Requires precise oxygen control |

| Multi-Stage Flash (MSF) | Feedwater pre-oxidation | Reduced scaling and corrosion | Higher oxygen injection cost |

| Electrodialysis | Metal ion removal | Improved effluent quality | Limited effect on refractory organics |

| Nanofiltration | Sulfur and metal removal | Reduced odor and scaling | Oxygen-resistant materials required |

Case Studies and Practical Experience

Thermal Power Plants

In power plants using saline water for boiler feed, controlled oxygen injection prior to pre-oxidation filtration reduced scaling by 30–40% and increased equipment lifetime by approximately 25%.

Municipal Brackish Water Desalination

In a municipal desalination facility, simple aeration systems removed over 90% of iron and manganese, significantly improving water taste and odor at minimal cost.

Future Outlook

With increasing water scarcity worldwide, oxygen-based strategies in desalination are gaining attention as cost-effective, controllable, and sustainable solutions. Future research suggests that combining oxygen with nanofiltration, hybrid desalination systems, and advanced oxidation technologies can further enhance water quality while reducing energy consumption.

The controlled application of oxygen in water desalination processes has a profound impact on water quality, system efficiency, and equipment longevity. Oxygen facilitates effective removal of dissolved metals and refractory organic compounds, reduces scaling and corrosion, and enhances overall operational performance.

From an economic and environmental perspective, oxygen-assisted desalination reduces chemical consumption, lowers maintenance costs, extends membrane and equipment life, and improves product water quality. When properly managed through precise injection systems and continuous monitoring, oxygen serves as a powerful and safe complementary tool for both industrial and municipal desalination facilities.

As global demand for freshwater continues to rise, oxygen-based desalination strategies represent a practical, sustainable, and forward-looking solution for ensuring reliable access to high-quality water.

————————————————–

References

1. Ghaffour, N., Missimer, T.M., & Amy, G.L. (2013). Technical review and evaluation of the economics of desalination: Current and future challenges for better water supply sustainability. Desalination, 309, 197–207.

2. El-Dessouky, H.T., & Ettouney, H.M. (2002). Fundamentals of Salt Water Desalination. Elsevier.

3. Shannon, M.A., Bohn, P.W., Elimelech, M., Georgiadis, J.G., Marinas, B.J., & Mayes, A.M. (2008). Science and technology for water purification in the coming decades. Nature, 452, 301–310.