This post is also available in: Persian Armenian

The importance of argon gas in the metal industry

Argon is a noble and inert gas that is found in the Earth’s atmosphere at an amount of about 0.94%. This gas is colorless, odorless and non-flammable and, due to its completely neutral chemical behavior, is used in many industrial processes as a protective medium or refining agent. In the metal industry, one of the most important applications of argon is its use for washing molten metals, or more specifically, gas purging. This process plays a key role in improving the final quality of the metal, removing impurities, and controlling the gaseous composition of the molten metal.

In melting and casting processes, metals usually dissolve some dissolved gases such as oxygen, nitrogen and hydrogen. These dissolved gases can cause bubbles, porosity, cracks and reduced mechanical strength in the final part during solidification. To avoid these problems, these gases must be removed from the melt before casting. One of the most effective and cleanest ways to do this is to inject argon gas into the molten metal.

The role of argon gas in refining and washing molten metals

1. The concept of gas refining

Gas refining is a method in which an inert gas, such as argon, is injected into the molten metal through special nozzles or lances. This gas disperses into the melt in the form of tiny bubbles and, as it moves towards the surface, carries dissolved gases and impurities out with it.

In effect, each argon bubble acts like a “gas carrier,” transporting unwanted gases from within the melt to the surface and eventually expelling them.

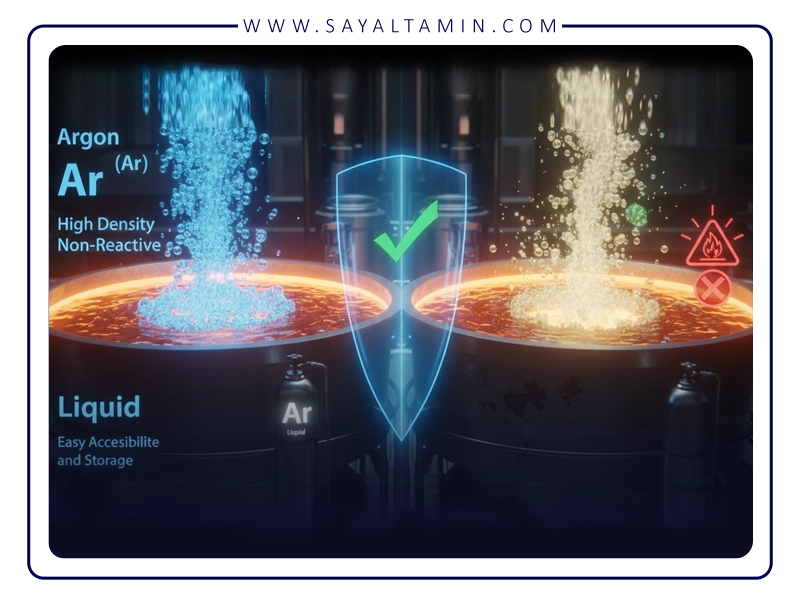

2. Special properties of argon

The reason for choosing argon over other gases is that:

- It is inert and inactive, so it does not cause any unwanted chemical reactions with the melt or alloys.

- It has a high density, which helps to better distribute bubbles throughout the depth of the melt.

- It is easily accessible and stored in liquid form.

- Compared to gases such as nitrogen or hydrogen, it is safer and more chemically stable.

Mechanism of action of argon in refining molten metals

When argon gas is injected into the melt from the bottom of the ladle or through a lance, it forms very small bubbles that, as they rise to the surface of the melt, absorb dissolved gases such as hydrogen or oxygen from the metal. This phenomenon follows the law of gas-melt phase equilibrium; the higher the partial pressure of a dissolved gas in the metal, the faster it will be transported into the bubble.

Simply put, argon creates a slight pressure difference between the inside and outside of the melt, causing undesirable gases to tend to escape from the metal. Eventually, when the bubbles reach the surface, the trapped gases are released and the melt becomes “cleaner.”

Parameters affecting the quality of refining:

- Bubble size: The smaller the bubbles, the more surface area they create and the more effective the degassing process.

- Argon gas flow rate: If the flow rate is too high, the bubbles will become coarse and the effect will decrease. Conversely, if the flow rate is too low, the purification efficiency will also decrease.

- Melt temperature and viscosity: At higher temperatures, the movement of bubbles is faster and the gas exchange process is more effective.

- Nozzle or lance design: The precise design of the injection system (e.g., porous nozzle or multi-hole lance) plays a decisive role in uniform gas distribution.

Application of argon in various metal industries

1. Steelmaking industry

In steelmaking, argon plays a vital role in secondary refining stages.

In this stage, the molten steel, after leaving the furnace, enters the ladle for final refining. Argon injection at this stage is used to:

- Removal of dissolved gases such as oxygen, nitrogen and hydrogen

- Homogenization of the chemical composition of steel

- Reduction of non-metallic impurities

- It is used to improve the surface and structural quality of the final steel.

Processes such as VAD, VD and RH in the steel industry are based on the injection and circulation of argon gas. These systems accelerate the refining reactions by creating agitation in the melt.

2. Aluminum industry

In molten aluminum, the main gaseous impurity is hydrogen. The presence of hydrogen in aluminum causes porosity and a decrease in density in the final part. Argon injection here is carried out as a piercing with a rotating lance and effectively removes hydrogen from the melt.

In this process, a combination of argon and chlorine is usually used to increase the efficiency of removing gases and oxides.

3. Copper and nickel industry

In copper and nickel refining, argon is used to reduce dissolved oxygen and prevent re-oxidation. This increases the electrical conductivity of copper and improves its surface quality.

4. Application in cast iron and special alloys

In the production of graphite cast irons and special alloys (such as nickel superalloys), the use of argon helps maintain the precise composition of the elements and prevent their evaporation or oxidation.

Argon injection technologies and equipment

In modern metal industries, the method of injecting argon gas into the melt has a great impact on the refining efficiency, gas consumption, and final metal quality. The selection of the appropriate injection system is based on the type of metal, the volume of the melt, and the purpose of the refining operation. The most important technologies and equipment used are introduced below.

1. Porous nozzle

The porous nozzle is one of the most common and effective methods of argon injection, which is installed in the bottom of the ladle. This nozzle is made of highly porous refractory material, and argon gas enters the melt through its very fine pores.

This design makes the gas bubbles very small and uniform. As a result, the gas contact surface with the melt increases and the process of removing dissolved gases such as hydrogen and nitrogen is carried out more efficiently.

Other advantages of porous nozzles:

- Creating a smooth and uniform flow in the melt without creating excessive turbulence

- Increased refining efficiency due to uniform gas distribution throughout the melt

- Reduced argon gas consumption compared to direct injection methods

- Ability to precisely control the injection rate (Flow Rate) and operation timing

Of course, using a porous nozzle requires regular maintenance, as over time its pores may become clogged with oxide deposits.

2. Injection lance

In the lance method, argon gas is blown into the melt through a refractory tube (usually steel with a resistant coating). This method is most commonly used in cases where:

- Need for rapid or localized purification,

- Or there is no permanent floor nozzle equipment.

In steelmaking, the injection lance usually enters the ladle or furnace from above and can force gas into the melt at high pressure.

Unlike the porous nozzle, the lance method has larger bubble sizes, but the melt circulation speed and gas transfer occur over a wider area. This is very effective for homogenizing the chemical composition.

The advantages of this method:

- Possibility of use in small or semi-industrial units

- Ease of installation and transportation

- Ability to combine with other gases such as nitrogen or oxygen for specific operations

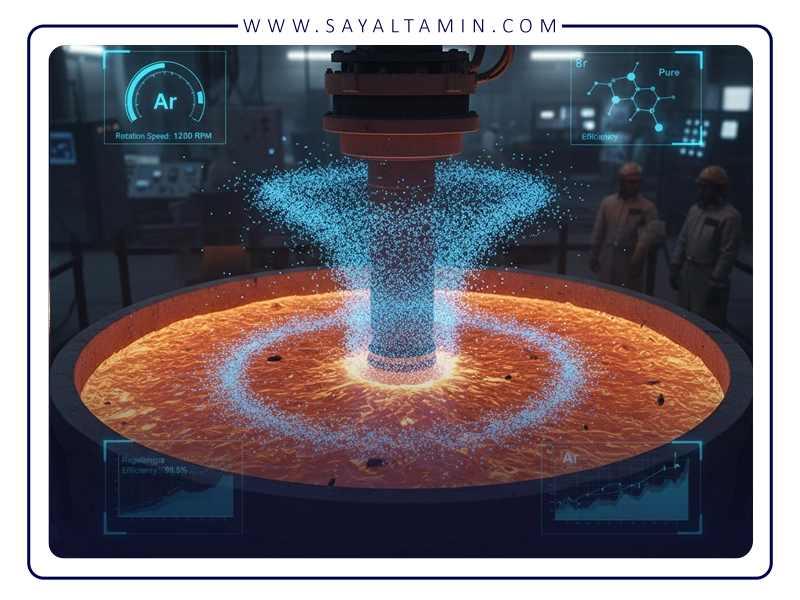

3. Rotating systems

Rotating systems are essentially a combination of gas injection and mechanical agitation. This technology is mainly used in the aluminum and light alloy industries.

In this system, argon gas is injected into the melt via a rotating shaft or impeller. The mechanical rotation causes the bubbles to collapse and disperse evenly throughout the large volume of melt.

Key features of this method:

- Creating very fine and uniform bubbles with longer retention in the melt

- Increasing the efficiency of hydrogen removal from molten aluminum

- Ability to be used in continuous casting lines

- Reduced operation time compared to traditional methods

Due to the effective combination of physical movement and gas injection, these systems can remove up to 90% of dissolved gases in a short period of time.

4. Multiphase systems (Ar + N₂ or Ar + He)

In many steelmaking units, inert gas mixtures are used to reduce the cost of argon consumption.

Combining argon with nitrogen (Ar + N₂) is one of the most common methods. Nitrogen is cheaper and does not negatively affect the quality of the steel at low concentrations.

In some special cases, a combination of argon with helium (Ar + He) is also used, as helium contributes to high gas permeability in the melt.

These systems typically feature automatic gas mixing ratio controllers to maintain precise and uniform mixing. As a result, operating costs are reduced by up to 30% while maintaining refining quality.

Economic and qualitative benefits of using argon

Injecting argon gas into molten metals, in addition to directly affecting the quality of the final metal, has significant economic benefits for manufacturers.

1. Increasing the quality of the final product:

By removing dissolved gases and reducing impurities, the mechanical properties, toughness, and strength of the parts are increased. In steelmaking, this results in cleaner steels with higher machinability and weldability.

2. Reduction of surface and internal defects:

The argon purification process prevents bubbles and porosity in the metal structure. This is especially important in the aerospace and automotive industries, where precision and strength of the part are critical.

3. Increasing melting efficiency and reducing metal losses:

Due to its inert nature, argon prevents the oxidation of expensive alloying elements such as manganese, chromium, and nickel. As a result, raw material consumption is reduced and production efficiency is increased.

4. Saving on flux and chemicals:

In the absence of argon, chemical fluxes or sintering agents are used to remove impurities, which are costly and polluting. The use of argon minimizes the need for these agents.

5. Stability of chemical composition and better quality control:

The gentle flow of argon in the crucible ensures uniform mixing of the melt, as a result of which the composition of elements remains constant throughout the volume of the crucible and the quality of each melt will be approximately the same.

Safety and operational considerations

Although argon is an inert and non-flammable gas, its industrial use without following safety precautions can be dangerous.

The density of argon in its gaseous state is about 1.4 times that of ordinary air. Therefore, in confined or confined spaces, it may replace oxygen and pose a risk of suffocation without warning.

Key safety tips:

1. Proper ventilation of the environment:

Argon injection and storage areas must have effective natural or mechanical ventilation to prevent gas accumulation.

2. Installing the oxygen sensor:

In places where there is a possibility of gas leakage, it is essential to install oxygen concentration measurement sensors. If oxygen decreases, an alarm is activated.

3. Pressure control and use of safety valve:

Argon cylinders and storage tanks are under high pressure. The use of a standard regulator and safety valve is vital to prevent explosion.

4. Personnel training:

Employees must be familiar with methods of transporting liquefied gas, safety precautions for connections, and how to respond in emergency situations.

5. Safe storage of liquid argon:

Liquid argon is stored at a temperature of about -186 degrees Celsius. Direct contact with it causes severe burns and frostbite to the skin, so the use of special gloves and cryogenic clothing is mandatory.

The Future of Argon Molten Washing Technology

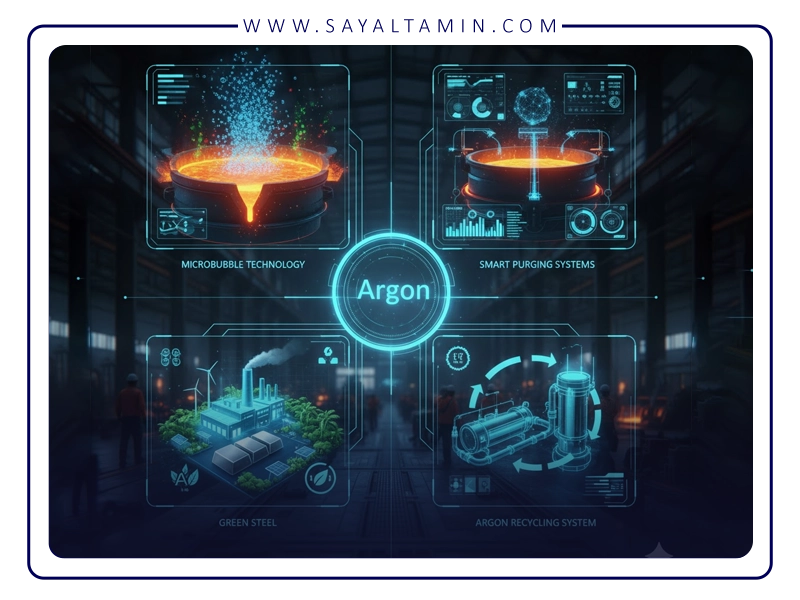

With the rapid development of technology and the increasing need to produce high-purity metals, gas purification systems are also evolving. In the last decade, several important innovations in the use of argon have been introduced:

1. Microbubble Technology

This technology uses advanced equipment to produce bubbles with a diameter of less than 1 mm. Smaller bubbles increase the contact surface with the melt and allow dissolved gases to escape more quickly.

The result of this technology is an increase in purification efficiency of up to 40% and a reduction in argon gas consumption of up to 30%.

2. Smart Purging Systems

In modern steelmaking, digital sensors and artificial intelligence-based control systems measure the amount of dissolved gas and the temperature of the melt in real time and adjust the argon flow rate accordingly.

This technology not only saves gas consumption, but also prevents human errors and ensures the quality of each melt.

3. Green Steel Technology

As industries move towards reducing emissions, the use of inert gases such as argon has taken on a special place. Unlike oxygen or chlorine, argon does not produce any pollutants and is therefore compatible with the environmental goals of the steel industry.

In “green steel” projects, argon injection is considered as part of the sustainable production process.

4. Argon Gas Recycling (Argon Recycling Systems)

Some new steelmaking units use closed systems in which argon gas is recycled and re-purified after leaving the ladle.

This technology drastically reduces the cost of gas consumption and is a major step towards optimizing energy consumption.

Argon gas is one of the most valuable industrial gases in metallurgical processes. Its inertness, suitable density, and high ability to remove dissolved gases make it an ideal choice for washing and refining molten metals.

In the steel, aluminum, copper, and nickel industries, argon plays a key role in improving quality, increasing efficiency, and reducing waste.

For companies active in the field of selling industrial gases and gas condensates, such as Sial Tamin Roham Company, supplying high-purity liquid argon gas and its injection equipment can be one of the most profitable and important parts of business activity.

Using argon in the washing of molten metals not only improves production quality, but also paves the way towards a cleaner, safer, and more efficient industry.

————————————————–

References

- ASM International (2005). Steelmaking and Refining Volume (ASM Handbook, Vol. 1). ASM International.

- Ghosh, A., & Chatterjee, A. (2015). Ironmaking and Steelmaking: Theory and Practice (2nd ed.). PHI Learning.

- Taylor, R., & Brown, R. (2013). Gas Purging in Metallurgy: Principles and Applications. Elsevier.

- The Aluminum Association (2019). Degassing and Refining Aluminum Melts.

- International Journal of Metallurgical Engineering (2021). “Argon Injection and its Effect on Inclusion Removal and Gas Content in Molten Steel.”

- Nippon Steel Technical Report (2018). “Advances in Secondary Metallurgy: Argon Stirring and Gas Control Technologies.”

- TMS (The Minerals, Metals & Materials Society) (2020). “Argon Purging Efficiency in Molten Metal Treatment.”

- Linde Gas (2022). Industrial Argon Gas Applications in Metal Production. Linde Technical Data Sheet.

- Air Products and Chemicals, Inc. (2021). Argon in Metal Processing — Gas Solutions Guide.

- European Steel Technology Platform (ESTEP) (2023). “Towards Green Steelmaking: The Role of Inert Gases.”