This post is also available in: Persian Armenian

Introduction

In industries ranging from oil and gas to petrochemicals, power plants and food processing, a common challenge is the accumulation of deposits and scale on equipment. These deposits can reduce thermal efficiency and equipment performance, increase pressures and shorten the useful life of equipment. For this reason, effective and safe methods for industrial cleaning are of great importance.

One of the new methods in this field is the use of dry ice, which is solid carbon dioxide that is thrown onto the surface by air pressure and removes deposits and debris. This method has been considered in many industries due to its environmental friendliness, low risk, and reduced need for chemicals.

The nature of carbon dioxide and dry ice

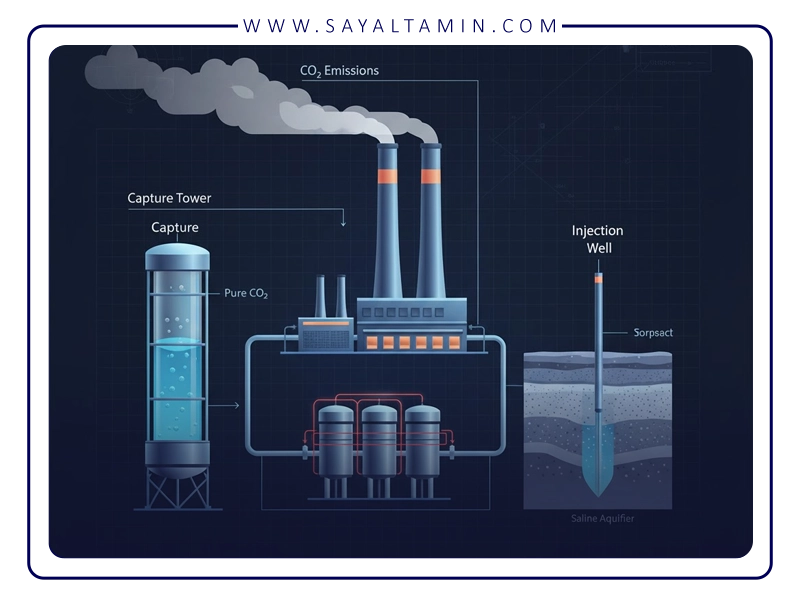

Carbon dioxide (CO₂)

Carbon dioxide is a colorless, odorless, nonflammable gas that occurs naturally in the air. It is produced or used in various industries, and one of its important derivatives is dry ice.

Dry ice

When CO₂ is compressed or cooled to a low temperature, it solidifies and forms dry ice. Dry ice has a temperature of about -78.5 degrees Celsius and has the interesting property of sublimating directly from solid to gas without turning into a liquid. This property means that no liquid residue is left behind during cleaning.

Why is dry ice good for cleaning?

The use of dry ice (solid CO₂) in industrial cleaning is highly effective due to three main mechanisms. Each of these mechanisms helps to remove deposits and debris in a unique way:

1. Thermal Shock:

Dry ice has a very low temperature of about -78.5 degrees Celsius. When these particles hit a surface, they cause a sudden and rapid contraction of the mass or deposit. This contraction creates internal stress in the deposited layers, which weakens their bond to the metallic or non-metallic surface.

o Practical example: In condensate pipes, mineral deposits such as calcium carbonate may form a hard layer. The impact of dry ice particles causes this layer to break without damaging the pipe.

o This mechanism is especially effective for brittle and brittle-adhesive deposits and eliminates the need for chemicals.

2. Sublimation & Lifting Effect:

When dry ice is heated, it turns directly into CO₂ gas and does not enter a liquid phase. This sudden increase in volume creates a small mechanical pressure beneath the sediment, which separates it from the surface.

o This process is similar to creating a cushion of gas that lifts the mass on the surface.

o Advantage: No liquid or chemical residue is created and no additional rinsing is required.

3. Mechanical force (Kinetic Impact):

In blasting, dry ice particles are hit at high speed against the surface. This impact causes the mechanical bond of the mass or deposit to break.

The higher the particle velocity, the greater the impact force and the more resistant deposits are removed.

o Practical application: Cleaning grease, oil or polymer materials on sensitive metal surfaces, without causing scratches or corrosion.

The combination of these three mechanisms allows the surface to be thoroughly cleaned without the need for water, chemicals or harsh mechanical tools. This feature makes Dry IceBlasting very suitable for sensitive surfaces, electronic equipment or critical process lines.

Dry Ice Blasting Method

Dry Ice Blasting is a process in which dry ice particles are propelled by compressed air onto a surface to remove contaminants, mineral deposits, hard coatings, and other debris. It is a dry, environmentally friendly method that, unlike waterjetting or sandblasting, leaves no water or chemical residue.

System components

• Dry ice source: Dry ice can be used in pellet, nugget or powder form. The particle size is selected depending on the type of surface and the degree of contamination.

• Compressed air compressor: Air pressure propels particles to the surface at the appropriate speed.

• Blasting nozzle: Nozzle design affects flow rate, spray angle, and flow focus.

• Hose and safety equipment: including eye and ear protection, cold-resistant clothing, and gloves.

• Proper ventilation: CO₂ is heavier than air and without ventilation, it can condense and become dangerous.

How it works

1. Dry ice particles are thrown at the surface at a controlled speed and angle.

2. Thermal shock and lifting effect cause the deposit to separate from the surface.

3. The impact force of the particles helps to separate even thick, sticky layers.

4. The separated particles and sublimation gas are easily collected or removed from the environment, without the need for washing or chemical disposal.

Implementation conditions

• Suitable air pressure: between 4 and 10 bars, depending on the type of sediment and surface.

• Particle speed and flow rate: The particle flow is between 50 and 300 meters per second to achieve maximum efficiency.

• Safety and ventilation: CO₂ is heavier than air and proper ventilation must be provided to prevent its concentration in the environment from becoming dangerous.

Applications in various industries

Descaling in gas and condensate lines

In condensate lines and process equipment, mineral deposits and hydrocarbon films can cause pressure drops and reduced efficiency. Dry IceBlasting, with its dry nature, can easily remove these deposits without damaging the equipment.

• Example: Removing calcium carbonate deposits in condensate pipes or separators without the need for long production shutdowns.

Cleaning sensitive surfaces

In the food, pharmaceutical or electronics industries, the use of water or chemicals may be dangerous or prohibited. Dry ice is an ideal option, converting directly to gas and leaving zero residue.

• Example: Cleaning electronic boards or pharmaceutical production line equipment without getting it wet or damaging the equipment.

General benefits

• Reduced equipment downtime: Fast operation without the need for complete equipment disassembly.

• Removes deposits without damaging the surface: Unlike sandblasting or waterjetting, metal and sensitive surfaces remain intact.

• Reducing chemical consumption: both to reduce costs and to comply with environmental requirements.

• Suitable for hard and sensitive surfaces: from steel pipes to electronic equipment, plastics and composites.

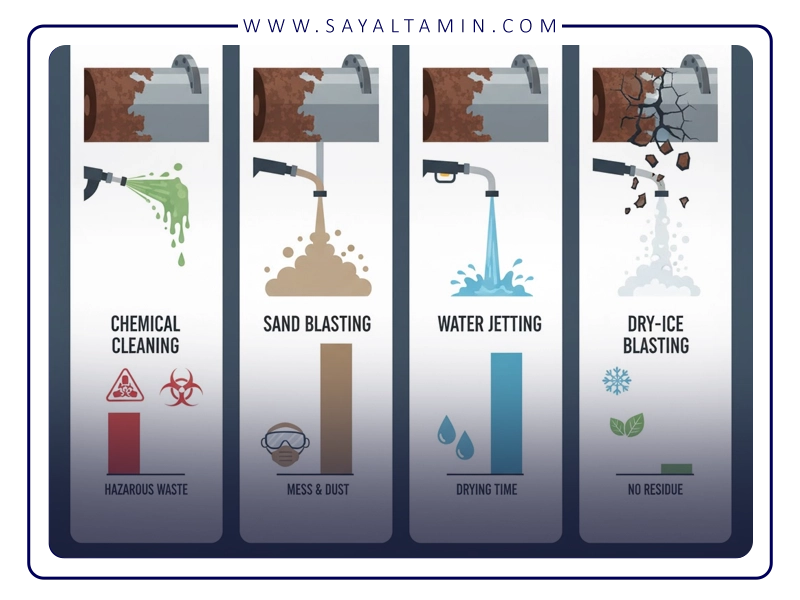

Comparison with traditional industrial cleaning methods

Industrial cleaning and descaling has always been one of the main challenges of various industries. Traditional methods such as acid cleaning, chemical cleaning, sandblasting and waterjetting, each have their own advantages and limitations. A close comparison of these methods with Dry Ice Blasting (Ice Blast) helps to better decide on the right method for each industrial application.

1. Acid washing and chemicals

Advantages:

• Capable of removing stubborn and adherent deposits, even thick and resistant mineral or hydrocarbon layers.

• Can remove complex chemical deposits without the need for mechanical force, which is the best option in some situations.

• Provides full surface cleaning for large industrial equipment where mechanical access is limited.

Limitations:

• High chemical consumption: The use of acids and alkalis is not only costly, but also requires special management of hazardous materials.

• Need for neutralization and disposal of residue: After washing, the acid or alkali must be neutralized and disposed of in compliance with environmental regulations.

• Long downtime: Lines or equipment must be taken out of service to perform pickling operations, which reduces production efficiency.

• Risk of corrosion and damage to equipment surfaces: If the choice of chemical or contact time is not properly managed, metal equipment or sensitive components may be damaged.

• Requires expertise to perform: The operator must have sufficient experience to control the chemical reaction and ensure safety.

Practical example: In a condensate distillation tower, calcium carbonate deposits may be so thick that they cannot be removed mechanically. Pickling with dilute acid and careful timing will remove the deposit, but requires collection and neutralization of the acid solution after the operation.

2. Sandblasting or waterjet

Advantages:

• Rapid removal of thick and hard layers: The mechanical impact of sand particles or high-pressure water flow is able to remove hard deposits.

• Pressure adjustment: By changing the pressure of the water flow or particles, the cleaning intensity can be controlled.

• Large surface area application: Suitable for cleaning tanks, reservoirs and large industrial equipment.

Limitations:

• High waste generation: Sand or water used after the operation must be collected and disposed of.

• Possibility of surface damage: In cases where the surface is sensitive or has a protective coating, mechanical impact can cause scratches or corrosion.

• High water and energy consumption: Using waterjet requires powerful pumps and significant water consumption, which is a limitation in some industries.

• Moisture risk for sensitive equipment: Electronic equipment or electrical appliances may be damaged.

Practical example: Cleaning steel pipes with thick oil and mineral deposits is usually done with a water jet. Although the deposit is removed, water and mud residue remain and require a long drying time.

3. Dry IceBlasting

Advantages:

• Dry and residue-free: Dry ice is converted directly into CO₂ gas, leaving no liquid or residue.

• Safe for sensitive surfaces: Works without scratching or corroding, even on soft metals, plastics, composites and electronic equipment.

• Reduced equipment downtime: Fast and feasible operations while equipment is still partially available.

• Environmentally friendly: No chemicals required, no liquid residue, and can be used in confined and sensitive environments.

Limitations:

• Relatively high initial equipment cost: Purchasing Dry Ice Blasting machines or supplying dry ice requires investment.

• For very thick deposits, this alone may not be enough: in some cases, a combined method with waterjet or chemicals may be necessary.

• Need for proper ventilation: CO₂ is heavier than air and in closed environments, ventilation or a CO₂ sensor must be in place.

Practical example: In gas condensate lines, oily and mineral deposits on sensitive metal surfaces are removed with dry ice without long downtimes and without damaging the surface. No liquid residue is created and the operation is fast, whereas with acid or waterjet, long downtimes and neutralization of the material were required.

Important tips for using CO₂ in industrial cleaning

To successfully implement Dry Ice Blasting and optimize performance, it is very important to observe the following points:

1. Identify the type of sediment and surface:

o Sediments can be mineral, hydrocarbon, or mixed.

o The surface material (metal, alloy, plastic, composite) determines what pressure and particle size to use.

o Example: Calcium carbonate deposits on stainless steel require larger particles and medium pressure, but oily deposits on plastic equipment are better removed with smaller particles and low pressure.

2. Choosing the right equipment:

o Air pressure, flow rate and particle velocity, dry ice particle size, nozzle angle and distance should be selected according to the surface and sediment.

o Different nozzles are designed for flat surfaces, corners and cavities to ensure complete operation.

o Practical example: For cleaning condensate tanks with tight angles, it is essential to use a flexible nozzle.

3. Safety:

o PPE (protective clothing, goggles, gloves, and ear protection) must be worn.

o CO₂ is heavier than air, so proper ventilation and CO₂ warning sensors are essential.

o Operators should be trained to avoid direct contact with dry ice particles, as very low temperatures can cause frostbite.

4. Determining a periodic maintenance schedule:

o Prevent future sediment buildup with regular cleaning.

o Scheduling periodic inspections and preventive cleaning will extend the life of equipment and reduce repair costs.

o Practical example: A gas refinery cleans its condensate lines every six months with Dry Ice Blasting to minimize deposits and maintain thermal performance.

The use of carbon dioxide and dry ice in descaling and descaling is a modern, effective and environmentally friendly method. This method:

• Allows equipment to be cleaned without the use of water or chemicals.

• Suitable for various industries, especially gas lines and sensitive equipment.

• Reduces equipment downtime and minimizes maintenance costs.

• With the right equipment selection, safety precautions and a regular maintenance schedule, it can provide the best results.

For companies and industrial units looking to supply high-quality CO₂ for industrial and cleaning applications, working with a reputable gas condensate supplier ensures quality, continuity of supply and optimal equipment performance.

————————————————–

References

1. Cold Jet. (n.d.). The definitive guide to dry ice blasting. Retrieved October 26, 2025,

from https://info.coldjet.com

2. Cold Jet. (n.d.). How does dry ice blasting work?. Retrieved October 26, 2025

3. Dry Ice Plus. (n.d.). How dry ice blasting works. Retrieved October 26, 2025,

from https://dryiceplus.com

5. ScienceDirect. (2021). Industrial use of dry ice blasting in surface cleaning. Retrieved October 26, 2025, from https://www.sciencedirect.com

6. Cold Jet. (n.d.). Dry ice blasting solutions. Retrieved October 26, 2025,

from https://www.coldjet.com/dry-ice-blasting/

7. Reliant Dry Ice. (n.d.). Dry ice blasting and cleaning. Retrieved October 26, 2025,

from https://www.reliantdryice.com/dry-ice-blasting-and-cleaning

8. Subzero Dry Ice. (n.d.). Advantages & disadvantages of dry ice blasting. Retrieved October 26, 2025, from https://subzerodryice.com/advantages-disadvantages-of-dry-ice-blasting/

9. Thompson Industrial Services. (n.d.). The benefits and risks of dry ice blasting. Retrieved October 26, 2025, from https://industrial.thompsonind.com