This post is also available in: Persian Armenian

Physical and chemical properties

Argon gas is an inert, colorless, and odorless element first discovered by Henry Cavendish in 1785, which turns a light blue when a high voltage is applied. More than a century later, in 1894, Scottish chemist William Ramsay and Lord Rayleigh (John William Stroud) discovered that nitrogen prepared by removing oxygen from the air was about 0.5 percent denser than nitrogen obtained from chemical sources such as ammonia. The heavy gas remaining after the removal of oxygen and nitrogen from the air was the first noble gas to be discovered on Earth, and was named after the Greek word for “lazy” because of its chemical inertness.

The element argon is located in the periodic table with the symbol Ar and atomic number 18. Argon, which is the third noble gas in group 8, makes up approximately 1% of the Earth’s atmosphere. Argon is 2.5 times more soluble in water than nitrogen, and its solubility is approximately similar to that of oxygen.

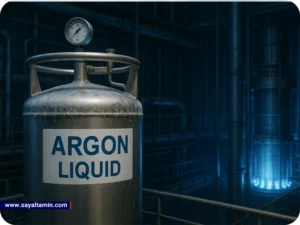

Liquid Argon Technical Specifications Table

| Unit | value | attribute |

|---|---|---|

| – | Ar | Chemical formula |

| – | 18 | Atomic number |

| g/mol | 39.95 | Molecular weight |

| C | 185.9- | Boiling point |

| C | 189.3- | Freezing point |

| C | 122.4- | Critical temperature |

| atm | 48 | Critical pressure |

| kg/m³ | 1394 | Density in the liquid state |

| kg/m³ | 1.656 | Density in the gas state |

| – | Colorless, odorless, tasteless | Color, smell and taste |

| % | 0.93 | Percentage of presence in the Earth’s atmosphere |

Download Liquid Argon Technical Specifications

To access the PDF file of technical specifications and safety tips for transporting and storing argon, download the file below.

This inert chemical element is inert in both its gaseous and liquid states. No real compound containing argon has been known to date. Since liquid argon uses a significant amount of heat to evaporate, it is considered an excellent refrigerant. Among its chemical properties, its density is 1394 kilograms per cubic meter. In fact, one liter of liquid argon is equal to 1.4 kilograms.

Read more: Use of Argon in the Steel Industry

Main steps in producing liquid argon

1. Air Separation

Argon is a component of air and makes up approximately 0.93% of the Earth’s atmosphere. The first step in producing liquid argon is to convert ambient air into a liquid state through compression and cooling (cryogenic distillation). In this process, the air is first compressed and then cooled to temperatures close to -200°C so that its components become liquid.

2. Cryogenic Fractional Distillation

After the air is liquefied, cryogenic distillation columns are used to separate its components based on their boiling points. Because the boiling point of argon (-185.9°C) lies between the boiling points of nitrogen (-196°C) and oxygen (-183°C), its separation requires high precision and staging. In this step:

- First, nitrogen and oxygen are separated.

- The raw argon stream with about 5% oxygen is then directed to a second distillation column.

۳. Argon purification

To achieve high commercial purity (around 99.999%), raw argon requires further purification and refining. At this stage, technologies such as:

- Oxygen absorption reactors

- Special filters (Catalytic Purifiers)

- And special dryers are used.

Finally, the pure argon gas is cooled again under pressure and converted into high-density liquid argon.

Alternative sources for argon production

In some cases, argon is produced as a byproduct of chemical processes such as:

- Ammonia production

- It is also extracted from petrochemical gas purification, but the main source is the process of distilling liquid air.

Why is argon produced in liquid form?

Due to its low boiling point and high cryogenic properties, argon requires transportation and storage in liquid form in many industries. The advantages of producing argon in liquid form include the following:

✅ Reduced volume (1 liter of liquid argon ≈ 800 liters of gas)

✅ Easier transportation in cryogenic tanks

✅ Direct application in sensitive industries such as welding, medicine and electronics

Equipment required for liquid argon production

- High pressure air compressor

- Cryogenic heat exchangers

- Fractional distillation columns

- Double-walled vacuum systems for storage

- Gas purification reactors

- Cryogenic storage tanks

Applications of liquid argon

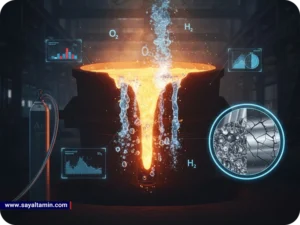

1. Application of liquid argon in the welding and metallurgy industry

One of the most important and common uses of liquid argon is in electric arc welding (TIG and MIG). Argon is used as a shielding gas to prevent the molten metal from reacting with oxygen and nitrogen in the air.

Target industries:

- Automotive

- Manufacturing of steel medical equipment

- Production of aluminum and titanium parts

- Welding of stainless steels

Why argon? Because it has high density and zero reactivity, it ensures arc stability and maximizes weld quality.

2. Use of liquid argon in refrigeration and cryogenic systems

Due to its very low temperature, liquid argon is used in refrigeration technologies and cryogenic laboratories to cool equipment or materials.

Example applications:

- Cooling of particle detectors in physics (such as LArTPC detectors)

- Use in research reactors

- Storage and transport of biological samples at very low temperatures

3. Application of liquid argon in research and basic science

In advanced laboratories, liquid argon is used in nuclear physics experiments, accelerators, and spectroscopic analysis due to its high purity and low temperature.

Example:

- Dark Matter Experiments in Quantum Physics

- Cooling silicon detectors in particle accelerators

- Inert environment for highly sensitive chemical reactions

4. Storage and handling of sensitive materials

In industries such as pharmaceuticals or advanced electronics, liquid argon is used as a protective medium for materials sensitive to oxygen or moisture.

Examples:

- Preservation of stem cells and biological tissues

- Safe transportation of nano and radioactive materials

- Microelectronic components storage environment

5. Use of liquid argon as a protective inert gas

In processes where it is necessary to prevent oxidation or unwanted reactions, liquid argon evaporates into gaseous argon, providing an inert environment.

Applications:

- Casting reactive metals (such as magnesium or aluminum)

- Annealing process in metallurgy

- Refining and purifying rare metals

Risks and safety

- Neither gaseous nor liquid argon is flammable and does not present a fire or explosion hazard in itself. However, they are usually stored under pressure and storage containers, whether gas cylinders or liquid tanks, should not be located in areas where there is a high fire hazard or where they may be exposed to excessive heat. Compressed argon gas containers may rupture violently if overheated by exposure to fire.

- Lubricated compressors that have been operated continuously in argon service for long periods of time should not be converted to air service without thorough cleaning, otherwise there is a risk that unoxidized pyrophoric deposits that may have formed in the machine will explode violently on contact with compressed air.

- This chemical element is absorbed by the human body through breathing. The risk of breathing in is that in environments where purification is not carried out, the amount of argon gas increases and quickly reaches a supersaturated state in the air, posing a risk of suffocation and suffocation.

Breathing argon gas causes dizziness, fatigue, headache, and suffocation. Death occurs if the person becomes unconscious and cannot protect themselves from this gas. When the oxygen level in the environment is low, death occurs within a few seconds. - In industrial environments, you must ensure that liquid argon does not come into contact with carbon or low-alloy steel.

- Never mix water with liquid argon. This will cause a large amount of it to evaporate and the water to freeze. If your hand or skin comes into contact with liquid argon, the area will get frostbite and will always turn red or turn gray or white. In this case, you should wet the area with lukewarm water and never use hot water.

- All people working with liquid argon must be equipped with protective glasses, gloves, etc.

- It should never come into contact with the skin or eyes as it will cause frostbite.

- To use a liquid argon cylinder, pressure reduction equipment must be used, and the valve must be closed after each use. Also, after the capsule and argon storage tanks are empty, they must be placed in a cool, well-ventilated place, away from any alkaline or acidic substances.

- Tanks containing liquid argon should be stored in a well-ventilated area. Avoid storing liquid argon tanks indoors or in a location that is not protected from weather changes.

- Tanks containing refrigerant liquids are equipped with pressure devices to control internal pressure.

- Refrigerant liquids must be stored, handled, and transported vertically.

- Avoid thermal and mechanical shock.

- Under no circumstances should any unprotected part of the body come into contact with pipes or equipment containing refrigerant fluids.

————————————————–

Sources:

Do you need liquid argon?

Contact us for pricing, purchasing advice, or to place a bulk order.

Yes, it is dangerous if it comes into direct contact with the skin or is inhaled in an oxygen-free environment.

In welding, medicine, electronics, semiconductor manufacturing, and steel industries.

Sial Tamin Roham Company supplies argon gas in various volumes. Contact number: 09134490305 and 03133204088