This post is also available in: Persian Armenian

A Dual Opportunity for Environmental Protection and Energy Economics Improvement

Methane (CH₄) is one of the most significant greenhouse gases worldwide. Although its total emission volume is lower than that of carbon dioxide, its global warming potential over a 20-year period is estimated to be more than 80 times greater than CO₂. A substantial share of global methane emissions originates from industrial activities, particularly coal mining and oil and natural gas production.

In coal mines, methane is naturally trapped within geological formations and is released during extraction operations. In oil wells, methane is emitted either as associated gas or through leaks from equipment, pipelines, and storage facilities, eventually entering the atmosphere.

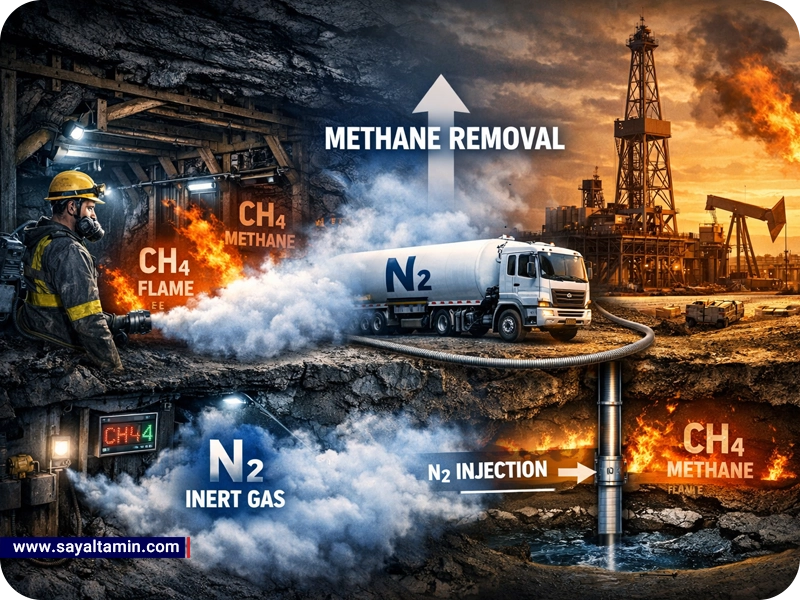

In this context, nitrogen, as an inert, abundant, cost-effective, and safe gas, plays a critical role in methane management. The use of nitrogen in processes such as methane containment, dilution, displacement, and even facilitation of methane recovery is recognized as an integrated solution that simultaneously reduces safety risks, controls greenhouse gas emissions, and improves economic efficiency.

This article examines the applications of nitrogen in controlling and removing methane from coal mines and oil wells, demonstrating how a simple industrial gas can become a key tool in sustainable energy management.

Methane in Coal Mines and Oil Wells: A Multidimensional Challenge

Safety Hazards

Methane is a highly flammable gas and forms an explosive mixture with air at concentrations between 5% and 15%. In coal mines, methane accumulation in underground tunnels can lead to catastrophic explosions, posing severe threats to workers’ lives and mining infrastructure. As a result, methane ventilation and control are among the most critical safety requirements in mining operations.

Similarly, in oil wells, methane accumulation in storage tanks, pipelines, or confined spaces can cause fires and explosions, particularly during maintenance operations or production shutdowns.

Environmental Impacts

Methane plays a major role in climate change. According to international reports, approximately 30% of current global warming is attributed to methane emissions. Small but continuous leaks from wells, compressors, flaring systems, and transmission lines collectively result in significant emission volumes.

In coal mining, a large portion of extracted methane is directly vented into the atmosphere because its concentration is too low for efficient energy use or due to the lack of recovery infrastructure.

Economic Challenges

On one hand, methane containment and removal require investment in equipment, continuous monitoring, and advanced technologies. On the other hand, methane itself is a valuable energy resource. If it can be safely collected and utilized, it can be converted into a revenue stream. This is where nitrogen emerges as a highly effective supporting tool.

Why Nitrogen Is Suitable for Methane Management

Nitrogen constitutes approximately 78% of Earth’s atmosphere and is an inert, non-flammable, and non-toxic gas. These properties have made it widely used across industries as both a safety gas and an inerting gas.

Key characteristics that make nitrogen ideal for methane control include:

- Chemical inertness: It does not react with methane or form hazardous compounds.

- Oxygen concentration reduction: By displacing air, nitrogen effectively lowers explosion risk.

- Industrial availability: Large-scale production via Air Separation Units (ASUs) or nitrogen generators is feasible.

- High-pressure injectability: Suitable for underground applications and oil wells.

- Relatively low cost: More economical than other inert gases such as argon.

Applications of Nitrogen in Coal Mines

1. Explosion Risk Mitigation through Methane Dilution

One of the simplest and most effective uses of nitrogen in coal mines is its injection into high-risk areas to reduce methane and oxygen concentrations. By increasing nitrogen content, the atmosphere is shifted into a non-explosive range. This method is particularly effective in abandoned tunnels, sealed seams, or post-fire scenarios.

Nitrogen injection results in:

- Suppression of combustion reactions

- Prevention of fire propagation

- Creation of safer conditions for operations

2. Control of Underground Fires

Fires in coal seams can persist for months or even years. By eliminating oxygen from the combustion zone, nitrogen becomes one of the most effective methods for extinguishing such fires. Continuous nitrogen injection reduces oxygen concentration below the level required for combustion.

3. Supporting Methane Management for Energy Recovery

In some mines, Coal Mine Methane (CMM) recovery systems are installed. Nitrogen is used in these systems to control pressure, guide gas flow, and prevent oxygen ingress into collection pipelines. This enhances system safety and improves the quality of recovered methane.

Applications of Nitrogen in Oil and Gas Wells

1. Equipment Purging and Safety Preparation

Before maintenance activities or recommissioning pipelines and storage tanks, methane and other flammable gases must be removed from the system. Nitrogen is used as a purging gas to bring internal environments to safe conditions.

This process:

- Reduces explosion risks during maintenance

- Enables hot work operations

- Ensures compliance with industrial safety standards

2. Prevention of Methane Emissions from Storage Tanks

In certain oil and condensate storage tanks, the vapor space above the liquid is filled with nitrogen (nitrogen blanketing). This nitrogen layer prevents contact between hydrocarbon vapors and oxygen while simultaneously reducing methane emissions into the atmosphere. This method lowers greenhouse gas emissions and preserves product quality.

3. Nitrogen Injection for Enhanced Oil Recovery (EOR)

In some reservoirs, nitrogen is injected to maintain pressure and facilitate oil movement toward production wells. In addition to improving recovery factors, this process can displace light gases such as methane toward controlled collection points, reducing uncontrolled leakage.

Comparison of Nitrogen with Other Methane Control Methods

| Methane Control Method | Safety Level | Operating Cost | Environmental Impact | Technical Complexity | Scalability |

|---|---|---|---|---|---|

| Natural Ventilation | Medium | Low | Direct methane emission | Low | High |

| Flaring | High | Medium | Methane converted to CO₂ | Medium | High |

| Methane Recovery | High | High | Very positive | High | Infrastructure-dependent |

| Nitrogen Injection | Very High | Medium | Prevents direct emissions | Medium | High |

As shown, nitrogen offers a well-balanced solution in terms of safety, cost, and environmental performance and is particularly effective as a complementary method alongside other technologies.

Economic Opportunities of Nitrogen Use in Methane Control

Reduction of Industrial Accident Costs

Explosions and fires result in significant losses due to production downtime, equipment damage, and human casualties. Preventive use of nitrogen can substantially reduce these risks and is economically justifiable.

Enhanced Methane Recovery Potential

When extraction environments are managed safely and in a controlled manner, the feasibility of installing methane recovery systems increases. Recovered methane can be used for power generation, industrial heating, or injection into gas networks, directly creating economic value.

Alignment with Carbon Reduction Policies

Many countries offer financial incentives, carbon credits, and funding mechanisms for methane emission reduction projects. Nitrogen-based methane control initiatives can qualify as environmental projects and attract investment.

The Role of Industrial Gas Suppliers in This Value Chain

Suppliers of industrial gases and gas condensates play a crucial role in implementing these solutions by providing nitrogen in various forms:

- Liquid Nitrogen

- Compressed Nitrogen Cylinders

- On-site Nitrogen Generation Systems

These options allow mining and oil projects to select the most suitable solution based on scale and operational requirements. In addition to gas supply, technical services such as injection system design, safety equipment selection, and operator training represent essential components of the value chain.

Challenges and Limitations of Nitrogen Utilization

Despite its advantages, nitrogen use is not without challenges. Transport and storage of liquid nitrogen require cryogenic infrastructure. In confined spaces, excessive nitrogen concentrations can reduce oxygen levels and pose asphyxiation risks, making continuous oxygen monitoring essential.

In some projects, nitrogen production or transportation costs may be high, necessitating thorough economic feasibility studies prior to implementation.

The Future of Methane Management through an Integrated Approach

Global trends are moving toward the combined use of multiple complementary technologies. Nitrogen is not viewed as a standalone replacement but as a core component of a comprehensive methane management system that includes:

- Smart leak detection and monitoring

- Methane collection and energy utilization

- Nitrogen use for safety and reaction control

- Emission reduction in storage tanks and transmission lines

The integration of these methods can simultaneously support environmental objectives and improve the profitability of energy projects.

Although methane is one of the world’s primary energy resources, improper management can turn it into a major contributor to climate change and industrial hazards. The use of nitrogen as a safe and inert gas offers an effective solution for explosion risk mitigation, fire control, methane leakage reduction, and facilitation of methane recovery in coal mines and oil wells.

From an environmental perspective, this approach directly reduces methane emissions, while economically it creates added value through accident reduction, productivity enhancement, and utilization of recovered methane. In this framework, the role of industrial gas and gas condensate suppliers in providing reliable nitrogen infrastructure and technical services is vital.

Ultimately, nitrogen should be viewed not merely as an industrial gas, but as a strategic tool in the pursuit of sustainable energy development—one that simultaneously serves safety, environmental protection, and economic efficiency.

————————————————–

Resource

Methane in Coal Mines & Oil/Gas Operations

1. IPCC (Intergovernmental Panel on Climate Change)

Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report. Cambridge University Press. (www.ipcc.ch)

2. United States Environmental Protection Agency (EPA)

Overview of Greenhouse Gases – Methane. (www.epa.gov)

3. Zhou, J., et al. (2020)

Coal mine methane control technologies and their implementation plans — International Journal of Mining Science and Technology.

4. IEA (International Energy Agency)

Global Methane Tracker 2024.(www.iea.org)