This post is also available in: Persian Armenian

In advanced science and high-technology industries, isotopes play a wide range of critical roles—from medicine and energy to fundamental research and materials characterization. Within this landscape, oxygen becomes especially important in isotope-separation workflows, particularly in areas such as nuclear-fuel production, industrial gas processing, and analytical quality control.

This article provides a comprehensive, technically grounded overview of isotope separation: what isotopes are, why separation matters, the main separation methods, and how oxygen—directly as an element and indirectly through oxygen-containing molecules—affects separation performance and industrial applications.

Isotopes and Why We Separate Them

What is an isotope?

An isotope is a variant of the same chemical element that has the same number of protons (therefore the same element), but a different number of neutrons. This difference changes the atomic mass while keeping chemical behavior largely similar.

For example, carbon has:

- Carbon-12: 6 protons, 6 neutrons

- Carbon-13: 6 protons, 7 neutrons

They behave similarly chemically, but their mass difference enables separation using physical and/or physicochemical techniques.

Why is isotope separation important?

Isotope separation enables key applications including:

- Nuclear medicine for diagnosis and therapy

- Nuclear energy (e.g., enrichment of specific uranium isotopes)

- Scientific research in chemistry, physics, geology, and environmental science

- Quality control and trace analysis in materials and industrial processes

In many real-world cases, we must enrich a lighter isotope relative to a heavier one (or vice versa). Isotope-separation technologies are designed to achieve this—often through many small separation steps combined in cascades.

Common Isotope-Separation Methods

Before focusing on oxygen’s role, it helps to understand the most widely used isotope-separation approaches.

1) Mass-dependent separation (distillation / phase-equilibrium routes)

When isotopes are present in molecules whose physical properties differ slightly (vapor pressure, boiling point, diffusion rate), phase-equilibrium or mass-transport methods can produce enrichment. These are typically weak per stage, but scalable through repeated steps.

2) Electromagnetic and electrostatic separation

If atoms or molecules are ionized, they can be separated using their mass-to-charge ratio (m/z) in electric and magnetic fields (e.g., mass spectrometric methods). These are highly selective but often costly and lower throughput for industrial bulk production.

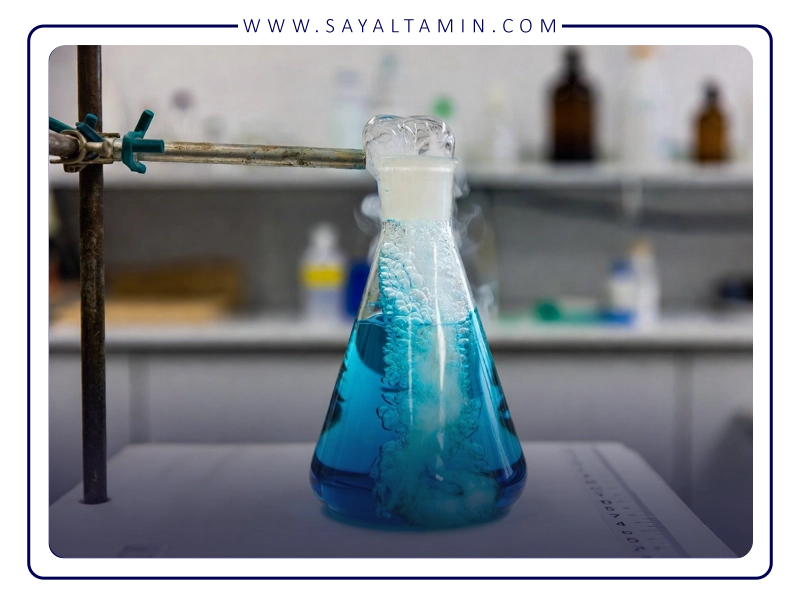

3) Chemical exchange

Some isotopes distribute differently between chemical species or phases at equilibrium, enabling enrichment via isotope fractionation. Even small differences in reaction equilibria or kinetics can be amplified through multi-stage exchange systems.

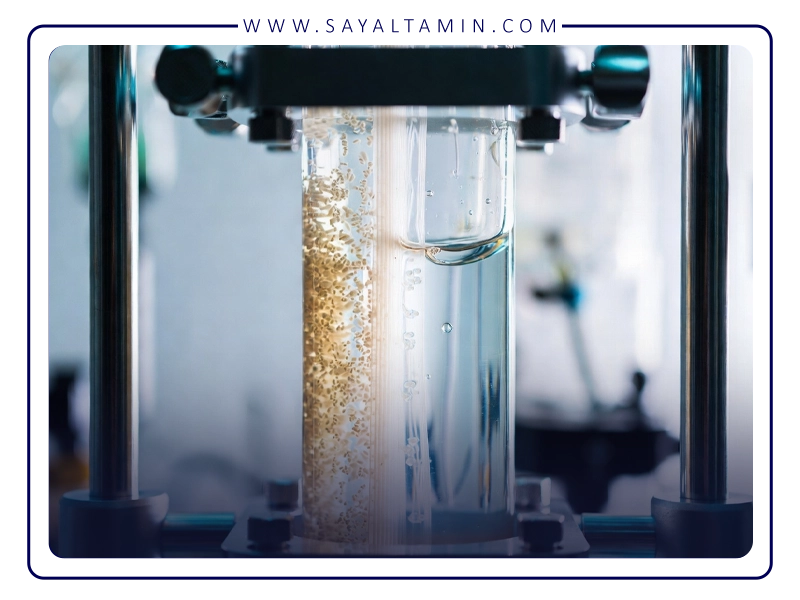

4) Membrane and molecular-sieving methods

Selective transport through membranes or porous materials can produce small but useful isotopic separation factors—again typically requiring staging or cascades for meaningful enrichment.

How Oxygen Influences Isotope Separation

Oxygen matters in isotope separation in two broad ways:

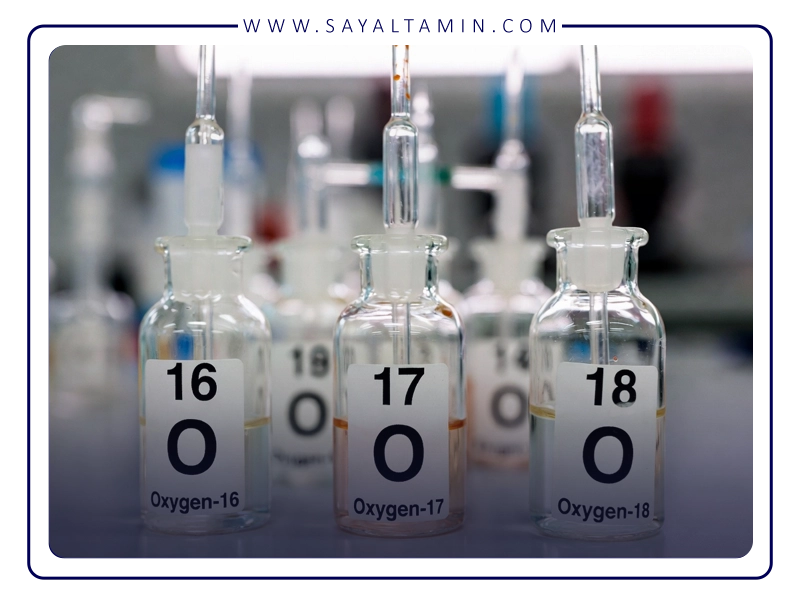

- Oxygen as the isotope of interest (e.g., ¹⁶O, ¹⁷O, ¹⁸O)

- Oxygen as a component in oxygen-bearing molecules that are processed for separation, purification, or analytical enrichment (e.g., CO₂, H₂O, metal oxides)

1) Oxygen in oxygen-bearing molecules used as process media

Many practical isotope workflows rely on processing gaseous or volatile chemical forms. Oxygen-containing molecules often have favorable properties for separation because their vibrational spectra, diffusion behavior, and phase equilibria shift measurably with isotopic substitution.

Common oxygen-bearing molecules used in isotope science and industry include:

- CO₂ (widely used for oxygen isotope exchange and analysis)

- H₂O / steam (important for isotope exchange, fractionation, and tracer work)

- Metal oxides and oxygen-ionic conductors (used in electrochemical isotope separation concepts)

Note (technical correction for accuracy): uranium enrichment typically uses UF₆ (uranium hexafluoride), which contains fluorine, not oxygen. Oxygen becomes relevant in the uranium oxide fuel cycle (e.g., UO₂), in analytical chemistry, and in oxygen-bearing process streams—but UF₆ itself is not an oxygen-containing molecule.

2) Oxygen’s effect on key physical properties

When oxygen is part of a molecule, it can strongly influence:

- Molecular mass and reduced mass (affecting diffusion and kinetic separation)

- Bond energies and vibrational frequencies (critical for laser selectivity)

- Polarity, viscosity, and density (affecting transport and membrane performance)

Because isotope separation often depends on very small mass-dependent differences, oxygen’s presence in a molecular structure can either amplify or diminish separation efficiency depending on the mechanism used.

3) Isotope-dependent chemistry involving oxygen

In chemical exchange and kinetic fractionation, isotopes can show slightly different behavior due to mass-dependent changes in reaction rates or equilibrium constants. Oxygen isotope effects are widely exploited in:

- Oxygen isotope fractionation in gas–solid adsorption/desorption

- Isotopic labeling in organic molecules

- Catalytic and surface reactions where oxygen participates directly

4) Oxygen interactions with membranes and separation materials

In advanced membrane systems, oxygen-bearing species may:

- Alter effective molecular size and permeation behavior

- Affect membrane stability (some oxygenated species can be corrosive or reactive depending on conditions)

- Enable specialized separation concepts using oxygen-ion conducting ceramics

Real Industrial Applications

1) Nuclear energy and fuel-cycle relevance

Isotope separation is central to nuclear energy—especially enrichment of specific uranium isotopes. While uranium enrichment commonly relies on UF₆, oxygen plays important roles elsewhere in the nuclear fuel ecosystem:

- Uranium fuel is typically fabricated as uranium dioxide (UO₂)

- Oxygen-related chemistry is essential in fuel processing, oxidation control, and materials characterization

- Oxygen isotopes can be used as tracers in nuclear-materials research and monitoring

2) Industrial gases and oxygen isotope products

Enriched oxygen isotopes (¹⁷O, ¹⁸O) are widely used in:

- Academic research (mechanistic chemistry, catalysis)

- Kinetic studies and tracer experiments

- Spectroscopy and structural analysis

- Production of isotope-labeled compounds and specialty gases

3) Medical and scientific isotopes involving oxygen

Oxygen isotopes and oxygen-labeled precursors support several medical and research applications—especially where isotopic tracing is required. High isotopic purity is critical for reliability, regulatory compliance, and reproducibility.

Modern Separation Technologies Where Oxygen Matters

1) Laser-based isotope separation

Laser isotope separation relies on isotope-dependent spectral shifts: a laser tuned to a specific frequency can selectively excite molecules containing a target isotope.

Why oxygen matters here: oxygen-bearing molecules often show distinct vibrational/rotational features, and isotopic substitution (¹⁶O → ¹⁸O) measurably changes absorption frequencies. This can:

- Increase spectral selectivity between isotopologues

- Improve separation efficiency by targeting only the desired species

- Reduce side reactions by minimizing off-target excitation

2) Advanced membrane separation

Membranes and molecular sieves can separate isotopologues based on subtle differences in:

- Diffusion rates

- Molecular interactions with pore surfaces

- Effective kinetic diameter under operating conditions

Oxygen-containing molecules (like CO₂ or water-derived species) are frequently used in lab-scale isotope separation and enrichment schemes because they are easy to handle and analyze.

3) Nanotechnology-enabled approaches

Nanomaterials can be engineered with highly specific surface chemistry and pore structures. Oxygen-bearing molecules may interact differently with these surfaces depending on isotopic composition—enabling improved separation factors or lower energy consumption in specialized systems.

Challenges and Limitations

1) Chemical complexity

Many oxygen-containing compounds can introduce reaction pathways or material compatibility issues that require tight control of:

- Temperature and pressure

- Moisture and contaminants

- Surface reactivity and corrosion risk

2) Capital and energy cost

High-performance isotope separation can be expensive due to:

- High-speed centrifugation systems

- Vacuum and containment infrastructure

- Precision lasers and control electronics

- Multi-stage cascades required for meaningful enrichment

3) Safety and environmental controls

Some industrial isotope processes involve hazardous materials. For example, UF₆ (while not oxygen-bearing) is highly reactive with moisture and demands strict handling protocols. Oxygen-bearing reactive species can also require robust containment and monitoring.

Economic and Strategic Value

1) Nuclear fuel supply

Reliable isotope separation supports:

- Higher reactor efficiency

- Better fuel utilization

- Potential reductions in waste intensity (depending on fuel strategy)

2) Scientific and analytical markets

Oxygen isotopes (¹⁶O/¹⁷O/¹⁸O) enable high-value applications in:

- Metabolic tracing and biochemistry

- Geochemistry and climate reconstruction

- Pharmaceutical research and radiochemistry workflows

3) Specialty gas and high-purity product markets

Industrial gas suppliers can create high value by delivering:

- Enriched oxygen isotopes and oxygen-labeled gases

- High-purity CO₂ or O₂ for advanced research

- Technical support for isotope handling and analytical validation

Isotopes are mass-distinct variants of the same element, and separating them is essential for modern technology. Oxygen plays a meaningful role in isotope separation—most directly through oxygen isotopes themselves, and indirectly through oxygen-bearing molecules and materials that influence transport, spectroscopy, and reaction pathways.

With continued progress in laser methods, advanced membranes, and nanostructured separation materials, isotope separation is expected to become:

- More energy-efficient

- More selective and higher purity

- Safer and better controlled

For industrial gas suppliers and advanced materials industries, oxygen-related isotope products represent a growing high-value niche—supporting the future of energy, research, and precision manufacturing.

————————————————–

References

1. Isotope separation and enrichment (Encyclopaedia Britannica)

www.britannica.com

2. Oxygen isotope fractionation of O₂ during adsorption and desorption (PubMed)

www.pubmed.ncbi

3. Oxygen Isotope Separation in Zirconia Electrolyte Cells (Nature)

www.nature.com

4. Principles of Stable Isotope Distribution (Book)

www.balyan.ir