This post is also available in: Persian Armenian

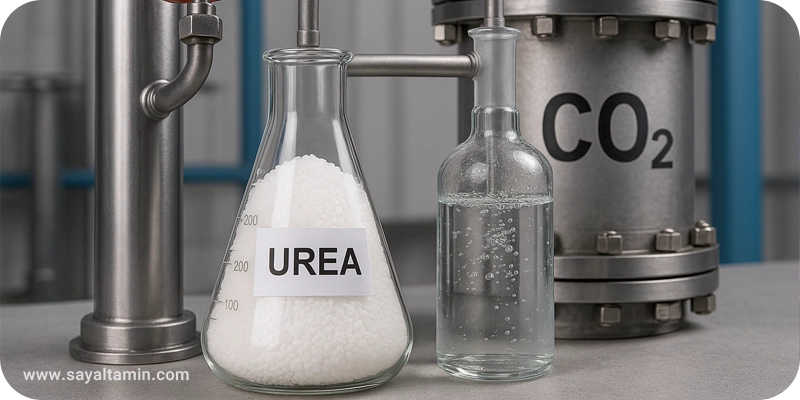

Urea [(NH₂)₂CO] is one of the most widely used nitrogen fertilizers in modern agriculture and is also an important material in various chemical industries. The mass production of this organic compound, which is the main supplier of nitrogen for plant growth, is carried out industrially and on a large scale. At the heart of this industrial process are two main raw materials: ammonia (NH₃) and carbon dioxide (CO₂). While the role of ammonia as the main source of nitrogen is well known, carbon dioxide also plays a vital and undeniable role in this industry as a source of carbon atoms. This article takes a deeper look at the use of carbon dioxide in urea production.

What is urea and why is it important?

Urea is an organic chemical compound with the chemical formula (NH₂)₂CO. It is actually the diamide of carbonic acid. Urea is a very important substance in agriculture and other industries for several reasons:

1. The main source of nitrogen for plants:

• Nitrogen is one of the three main nutrient elements (along with phosphorus and potassium) that is essential for healthy, strong plant growth.

• Urea contains about 46% nitrogen by weight, making it one of the richest nitrogen fertilizers available.

• After application to the soil, urea is converted by soil microorganisms to ammonia, then to ammonium ion (NH₄⁺), and finally to nitrate (NO₃⁻). Both ammonium and nitrate forms are available for plant roots to absorb.

• Nitrogen is essential for the production of proteins, nucleic acids (DNA and RNA), and chlorophyll in plants. Nitrogen deficiency leads to stunted growth, yellowing of leaves (chlorosis), and severe reduction in crop yield.

2. Easy transportability and storage:

Urea exists in solid form (white crystals or granules) at room temperature, which makes it much easier and safer to transport and store than gaseous or liquid ammonia.

This ease of transportation has led to urea being widely used around the world.

3. Application in other industries:

Resin production: Urea is used to produce urea-formaldehyde resins, which are widely used in the production of particleboard, medium-density fiberboard (MDF), adhesives, and coatings.

Animal feed: Urea can be used as a non-protein source for ruminants (such as cattle and sheep). Bacteria in the rumen of these animals can convert urea to ammonia and then use it for microbial protein synthesis.

Production of explosives: As we discussed in the previous article, urea is used in the production of some explosives through ammonium nitrate as a raw material.

Cosmetics and health industries: Urea is used in some skin care products due to its moisturizing properties.

Antifreeze: In certain applications, urea can be used as an antifreeze.

4. Economical:

Due to its mass production and efficient industrial processes, urea is usually one of the most affordable sources of nitrogen for farmers.

Urea production process

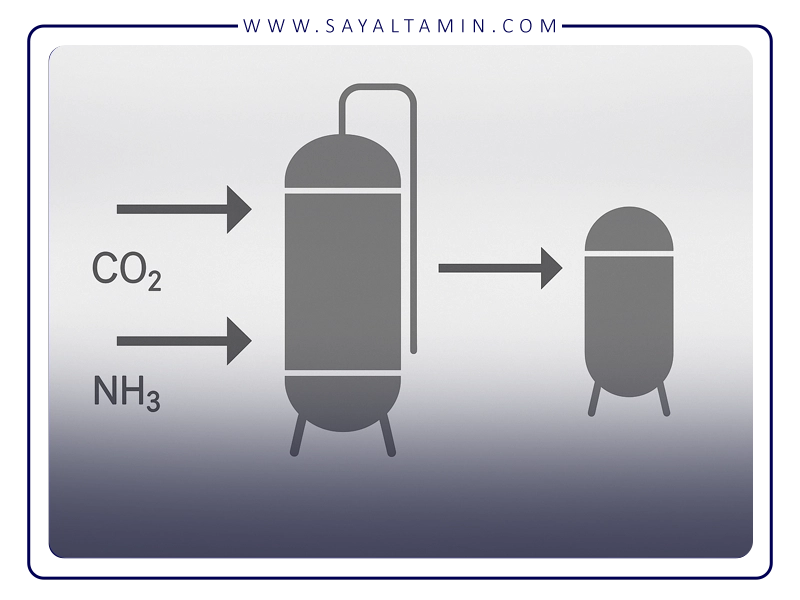

Urea production is based on a series of controlled chemical reactions between ammonia and carbon dioxide. The process, which is usually carried out at high temperature and pressure, involves two key steps:

| Read more: Use of ammonia in pharmacy |

1. Ammonium Carbamate Formation:

In the first step, liquid or gaseous ammonia reacts with carbon dioxide at relatively low temperatures (about 170-190 °C) and high pressures (about 140-170 bar) to form an intermediate compound called ammonium carbamate (NH₂COONH₄). This reaction is an equilibrium and exothermic reaction:

2 NH₃ (g) + CO₂ (g) ⇌ NH₂COONH₄ (s)

At this stage, carbon dioxide, as an electron acceptor and carbon source, bonds with ammonia, which acts as an electron donor, to form the ammonium carbamate structure.

2. Dehydration of Ammonium Carbamate to Urea:

The ammonium carbamate formed in the first step then decomposes at higher temperatures (around 190-210°C) and similar or slightly lower pressures to produce a urea molecule along with a water molecule. This step is the most key part of urea production and is essentially the dehydration reaction (loss of water):

NH₂COONH₄ (s) ⇌ (NH₂)₂CO (l) + H₂O (l)

In this reaction, the carbon atom that came from carbon dioxide is now in the urea structure and two amine groups (NH₂-) are attached to it. The water produced is also separated and used in other processes or recycled.

The strategic role of carbon dioxide

Carbon dioxide is not only an essential raw material, but also important in other aspects in the urea industry:

• Vital carbon source: Without carbon dioxide, the synthesis of the urea molecule, which has a central carbon atom, would not be possible. This gas directly supplies the carbon atom required for the urea structure.

• Economic and environmental optimization: In many ammonia production plants and other petrochemical industries, a significant volume of carbon dioxide is produced as a by-product. The use of this waste gas in the urea production process, in addition to reducing the costs of raw material supply, acts as an effective solution for reducing greenhouse gas emissions and optimizing resource utilization. This approach is called “decarbonization” (Carbon Capture and Utilization – CCU) and is in line with sustainable development goals.

• Process regulation: The amount of carbon dioxide feed relative to ammonia can affect the efficiency of the process and the rate of raw material recovery. Optimizing the ratio of these two materials in the reactor is essential to achieve maximum urea production efficiency.

| Be sure to read: Use of liquid ammonia in water purification |

Recycling and increasing efficiency

• Because the reactions are not complete, the remaining gases (NH₃, CO₂, and carbamate) are recycled back into the system to produce the maximum amount of urea, resulting in an overall yield of over 90%.

• The modern “stripping” method allows the high pressure itself to be maintained and only the carbamate component to be extracted and decomposed, increasing efficiency and safety.

How much energy is needed?

• Typical plants consume about 30 gigajoules of energy (mostly through steam or fossil fuels) to produce each ton of urea, with most of the consumption being related to the chemical reaction stage.

• More than 90% of these factories’ energy is supplied by fuels such as coal or natural gas.

Future path

• Researchers are working on methods that directly convert CO₂ and nitrogen (without ammonia) into urea under mild conditions and with special catalysts, methods such as electrochemical or plasma synthesis.

• If these technologies become practical and affordable, they could reduce energy consumption and greatly reduce CO₂ emissions.

Carbon dioxide, as one of the two main pillars of the urea production industry, plays an undeniable role in the production of this vital fertilizer. This gas is not only the source of the carbon atom in the urea molecule, but its use in the production process is also very important for economic and environmental reasons. Given the increasing importance of sustainable agriculture and the need to reduce the environmental impact of industries, understanding and optimizing the role of carbon dioxide in urea production will continue to be a research and operational priority in this industry.

————————————————–

References