This post is also available in: Persian Armenian

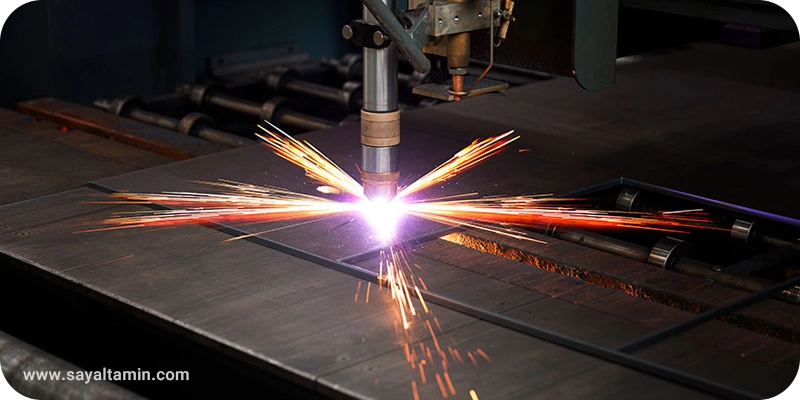

The metal cutting process is one of the core operations in heavy industries, construction, automotive manufacturing, maintenance of industrial equipment, and many other production sectors. Among the various cutting methods, Oxy-Fuel Cutting has earned a prominent place due to its efficiency, ease of use, cost-effectiveness, and adaptability in both workshop and field conditions.

At the heart of this process lies oxygen gas, an irreplaceable element. From generating the intense preheating flame to enabling the chemical reactions that drive the cut, oxygen plays a vital role in ensuring the success of oxy-fuel cutting operations.

This article provides a comprehensive technical review of oxygen’s function in cutting, its scientific principles, advantages, limitations, and essential safety requirements.

Scientific Principles of Oxy-Fuel Cutting

Two-step process: preheating and oxidation

A Two-Stage Process: Preheating and Oxidation

Oxy-fuel cutting relies on an exothermic chemical reaction between the base metal (typically iron or steel) and pure oxygen. The process takes place in two main stages:

1.Preheating:

The base metal is first heated with a flame generated by mixing a fuel gas (such as acetylene, propane, or methane) with oxygen until it reaches its ignition temperature (around 870 °C for carbon steels). This prepares the surface for the cutting reaction with pure oxygen.

2. Oxidation and Cutting:

Once the critical temperature is reached, a high-pressure stream of pure oxygen is directed at the heated spot. The oxygen reacts with the iron to form molten iron oxide. The exothermic reaction releases substantial heat, accelerating the melting of the metal. The resulting slag, which has a lower melting point than the base metal, is blown away by the oxygen jet, enabling a continuous cutting action along the kerf.

The Role of Oxygen in Cutting

Oxygen performs two critical functions in this process:

- Generating the Initial Flame:

Oxygen combined with a fuel gas produces an extremely hot flame, capable of exceeding 3,000 °C. This flame is used to preheat the base metal to the point where oxidation can occur. - Driving the Cutting Reaction:

In the second stage, pure oxygen at high pressure is injected onto the heated surface, directly participating in the oxidation reaction. The flow rate, purity, and pressure of the oxygen stream are key factors determining the speed, precision, and overall quality of the cut.

Advantages of Oxy-Fuel Cutting

- Capability to Cut Thick Metals:

Oxy-fuel cutting can handle thick steel plates, even over 300 mm, where alternatives such as plasma or laser cutting become less effective. - Cost-Effectiveness and High Productivity:

The equipment required for oxy-fuel cutting is relatively simple and inexpensive. Industrial oxygen and fuel gases like propane are much cheaper to operate compared to advanced systems such as lasers or waterjets. - High Portability:

The cutting torches, cylinders, and accessories are lightweight and portable, making them ideal for fieldwork and locations without electricity. This is especially valuable for repair and on-site operations. - Ease of Training and Operation:

Operators can be trained quickly to achieve high-quality cuts, contributing to the method’s popularity across both small workshops and large industries. - Compatibility with Ferrous Metals:

In addition to carbon steels, oxy-fuel cutting can be applied to cast iron and certain other ferrous alloys, though in some cases special techniques may be required.

Limitations of Oxy-Fuel Cutting

- Not Suitable for Non-Ferrous Metals:

Aluminum, copper, brass, and stainless steel are unsuitable for this method because they do not form oxides with sufficiently low melting points. Plasma or laser cutting is preferred for these materials. - Slag Formation and Cleanup Requirements:

Molten oxides and slag accumulate in the kerf and must be removed mechanically to ensure a clean finish. - Heat-Affected Zone (HAZ):

The high flame temperature creates a heat-affected zone around the cut, potentially altering the metallurgical structure of the material. For critical or stressed components, post-cut heat treatment may be required. - High Safety Risks:

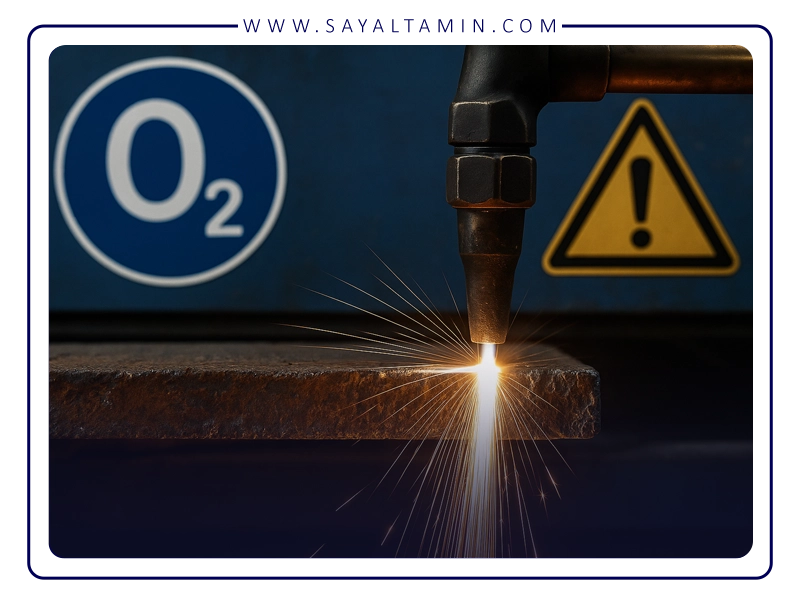

Oxygen is a powerful oxidizer, and when combined with flammable gases like acetylene, it significantly increases the risk of fire and explosion. Strict safety procedures and use of certified equipment are essential.

| Read more: Use of oxygen in the steel industry |

Safety Requirements for Oxygen Use

Due to the high potential hazards, the safe handling of oxygen in cutting requires strict adherence to technical and safety guidelines:

- Avoid Contact with Oils and Grease: Oxygen can react explosively with oils. Tools and hands must be clean and dry.

- Use Standardized Equipment: Torches, regulators, hoses, and valves must be from reputable manufacturers and comply with industrial standards.

- Provide Adequate Ventilation: Gas accumulation can lead to explosions; proper industrial ventilation is mandatory.

- Cylinder Safety: Oxygen cylinders must be stored upright, secured, and kept away from heat sources or sparks.

- Release Residual Pressure: After completing the job, residual gas in hoses should be vented and valves closed.

Personal Protective Equipment (PPE): Operators must wear welding masks, heat-resistant clothing, leather gloves, and safety footwear.

| Read more: What is liquid oxygen? |

Oxygen gas is the driving force behind oxy-fuel cutting, playing a pivotal role in enabling fast, precise, and economical cutting of ferrous metals. However, effective use of this technology requires not only an understanding of its mechanisms but also awareness of its limitations and a strong commitment to safety practices.

Ultimately, the choice of cutting method depends on material type, thickness, desired quality, and working environment. Yet in many industrial applications, oxygen remains a cornerstone of efficient and reliable cutting operations.

————————————————–

References