Flasks are designed for the storage and distribution of cryogenic liquids in small volumes, typically used in material science laboratories, biological sciences, in vitro fertilization (IVF) clinics, and some research institutes.

These vessels are dual-walled containers, with the two reservoirs connected by a fiberglass neck. During the manufacturing process, a vacuum is created between the two containers. The vacuum between the outer and inner reservoirs provides excellent thermal insulation, which slows down the evaporation rate of the cryogenic liquid compared to when it is exposed to the air.

For example, as long as liquid nitrogen is still in the vessel and evaporation is occurring, the nitrogen vapors inside the flask are as cold as -160°C (-320°F), keeping stored reproductive cells at the appropriate temperature for artificial fertilization.

The inner vessel is suspended from the outer shell by a neck structure. One of the weakest areas in small capacity flasks are the welds that connect the neck of the vessel to the inner chamber and to the top of the outer chamber. The entire weight of the flask is supported by this neck (Figure 1).

Therefore, all safety precautions should be followed when working with the vessel. The vessel is equipped with a cover-like lid (made of styrofoam) that is designed to allow gas to escape during evaporation. This design helps maintain a stable internal dynamic between the volume of the liquid gas and the vapor, resulting in slow but steady evaporation of the liquid. This structure also prevents pressure buildup and the entry of moisture and air into the flask.

The outer shell is made of aluminum, and due to the sensitivity of this alloy, care must be taken to avoid dents or damage. Even minor damage can lead to the loss of the vessel’s insulating ability, compromising the containment of the liquid. Metal fatigue and structural stresses can also gradually result in the loss of vacuum and an increase in the evaporation rate of the liquid.

Maintenance and Care:

Transport and Handling:

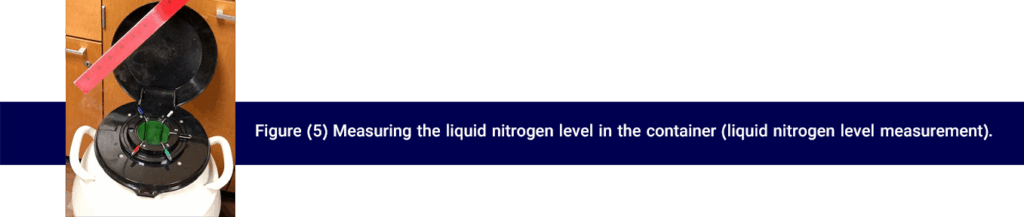

Monitoring Evaporation Rate:

The rate of evaporation of the liquid inside the flask depends on the frequency of opening the flask, the type of flask, and its integrity.

Tank Damage:

When inserting the spoon into the flask, ensure it is completely dry.

Over time, or due to rough handling, the flask’s lid or spoon may become damaged and no longer function properly. In such cases, seek replacement parts or repairs. A faulty lid or spoon can lead to significant cryogenic liquid evaporation.

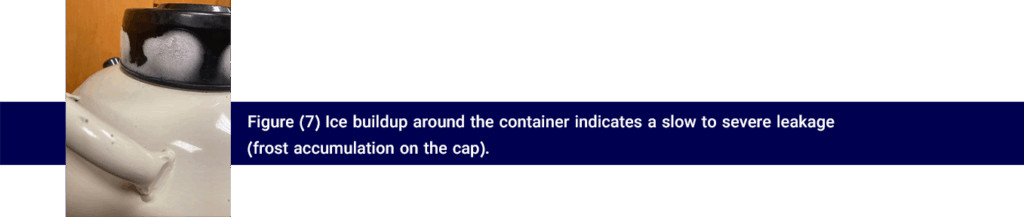

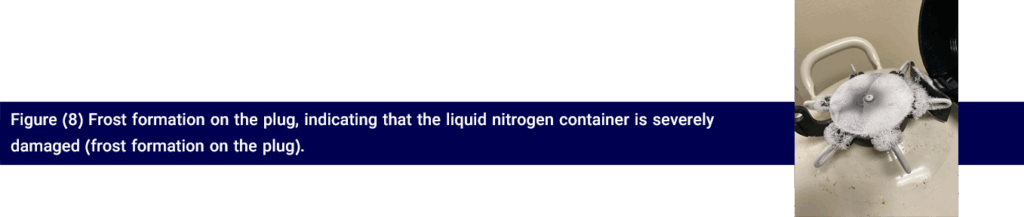

Although liquid flasks have the potential to last for many years with proper care, they will eventually fail due to the loss of vacuum and the reduction of the flask’s insulation. The evaporation rate of the flask should be regularly checked (Figures 8 and 7).

Frost on the outer shell indicates that dents or damage to the outer shell have compressed the insulating material between the two inner and outer walls, allowing heat from the surrounding environment to penetrate.

Frost around the lid suggests a slow vacuum leak, commonly seen in older tanks. To prevent further damage to the flask’s contents, immediate repair or replacement should be considered.

Complete icing on the outer shell indicates total loss of the flask’s vacuum. In such a case, immediate action should be taken. Complete loss of vacuum means you have only a few hours to transfer the contents to another container before the liquid inside completely evaporates.

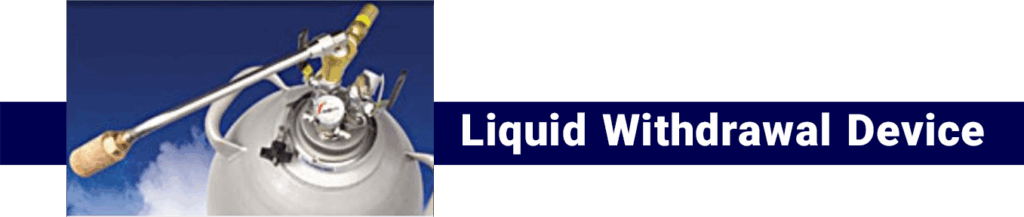

Liquid Withdrawal and Pressure Raising Device:

The liquid withdrawal device facilitates the extraction of liquid from the flask by applying the appropriate working pressure. This device is directly connected to the flask’s designated neck flange. The flow rate of this device is 8 liters per minute, with a working pressure of 0.5 bar (7.25 psig). This device is commonly used in cryotherapy by medical professionals.

Wheeled Base:

This base supports the weight of the flask while allowing you to move the device safely. The unit is equipped with five bearing wheels for smooth movement.